Manufacturing Execution System (MES)

Automated, intelligent networking of machines in modern production systems

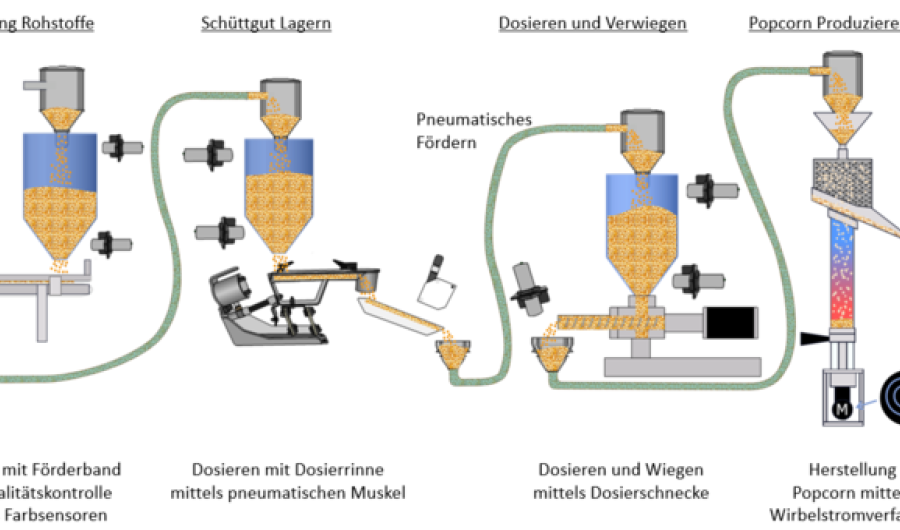

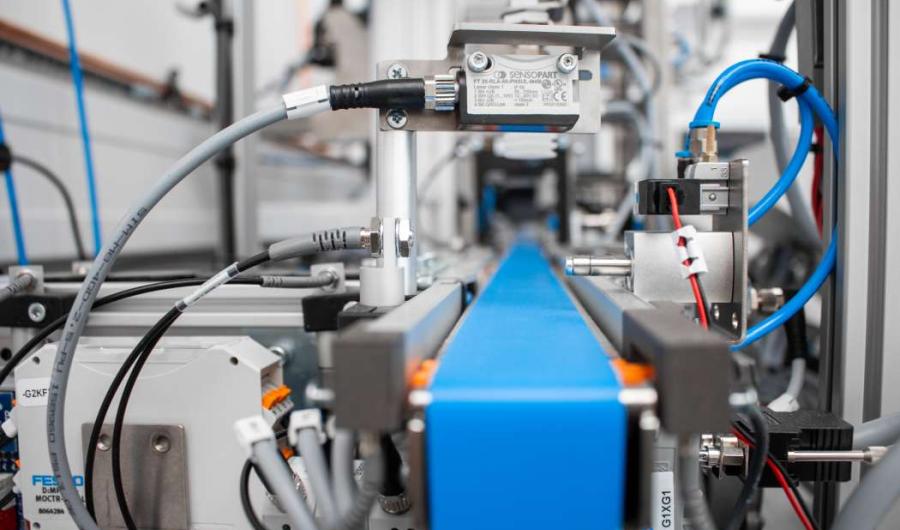

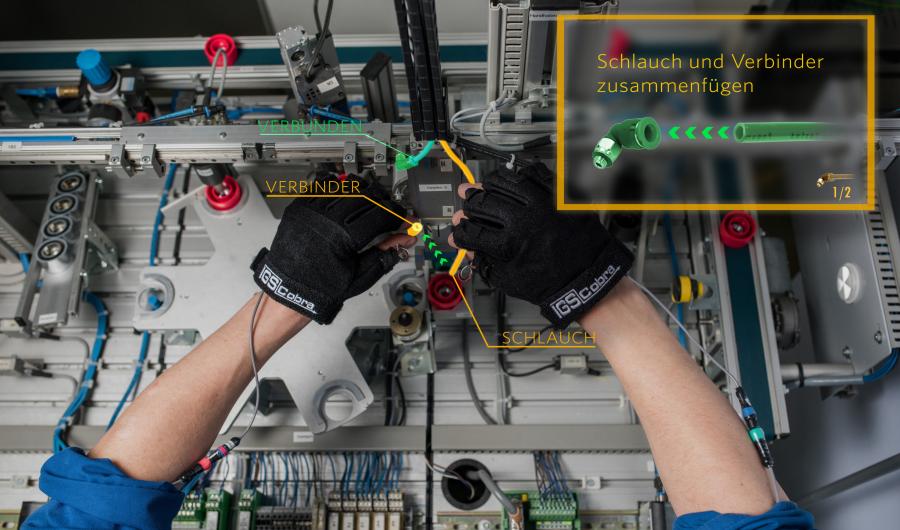

Modern production systems are characterized by automated, intelligent networking of machines and processes through the use of information and communication technologies.

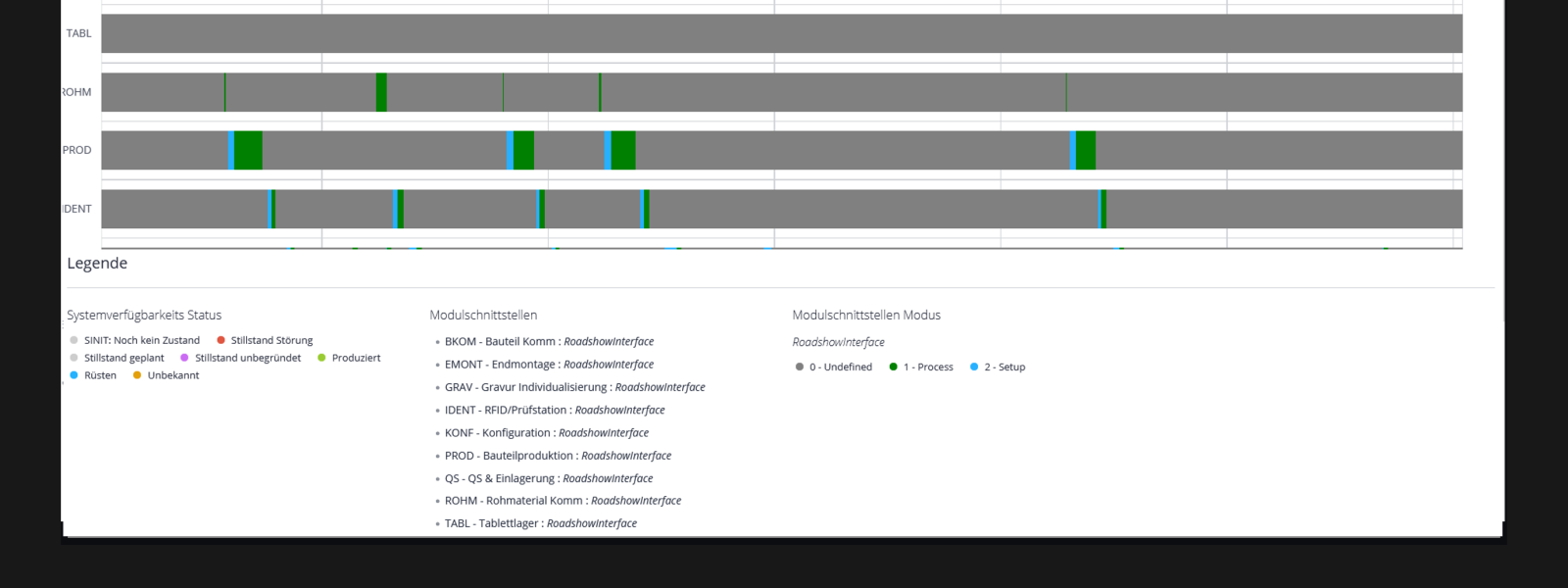

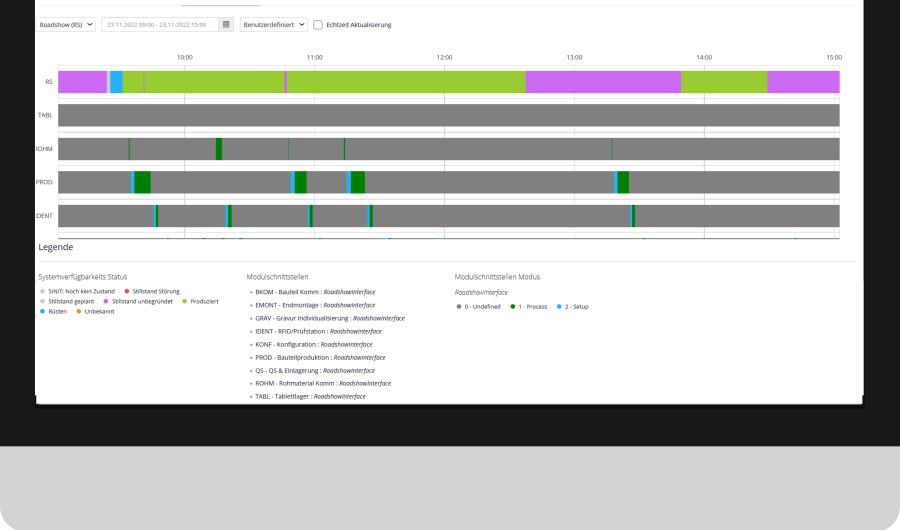

Manufacturing Execution Systems (SME) are also used to map the value stream of a company in real time. This feature is not possible in Enterprise Resource Planning (ERP). The requirement for process capability, now a verification obligation, results in the need for the manufacturer to align all value-adding processes with the process result and with the customer. MES process control systems are defined by a direct link to the distribution system of the process, enabling control of production in real time. The potential gain from the implementation of MES matches to the need for immediate, up-to-date online information. This allows users of the MES computer system to make the best possible decisions about the use of inventory, operating resources and the workforce.

Other benefits include: Reduction in manufacturing cycle time, data entry time, work-in-process inventory, lead time and paper use. In addition, customer service is improved and it becomes possible to react better to upredictable events.

SME systems hold especially for large companies a great advantage. In advance, the potential savings should be compared to the acquisition costs.

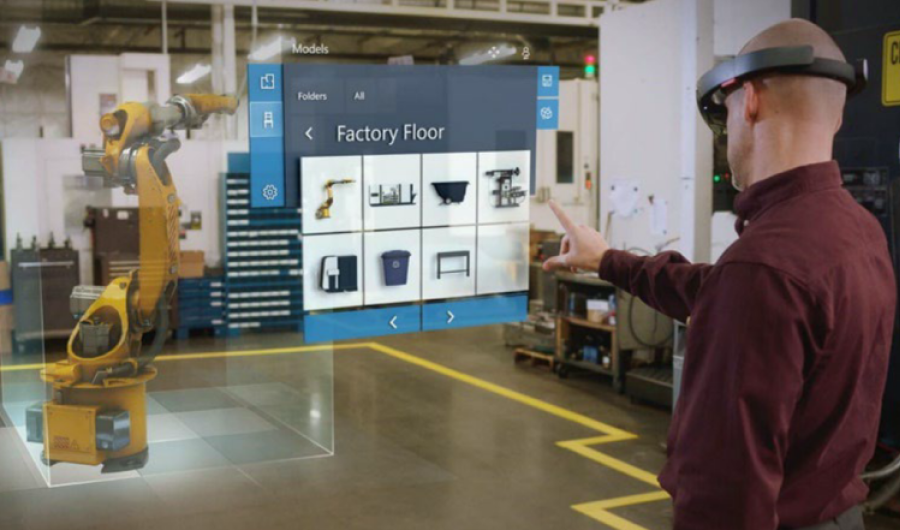

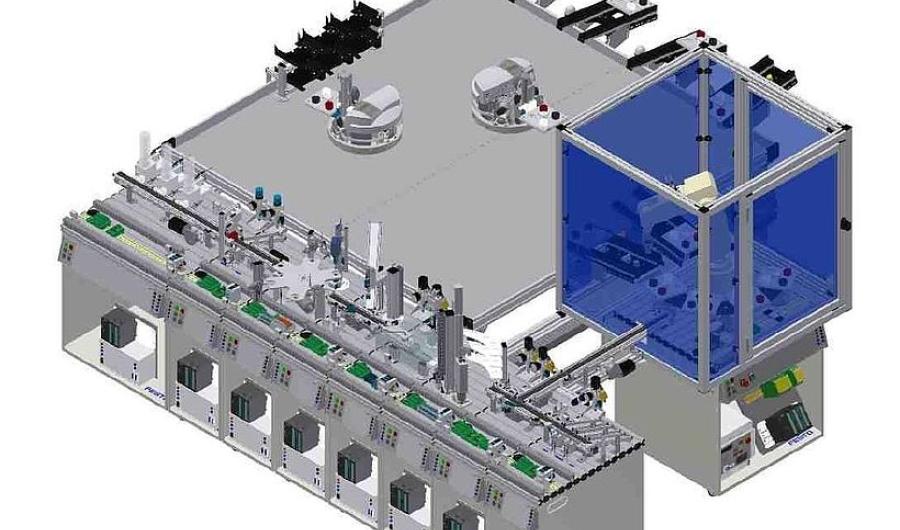

Where can you access this demonstrator?

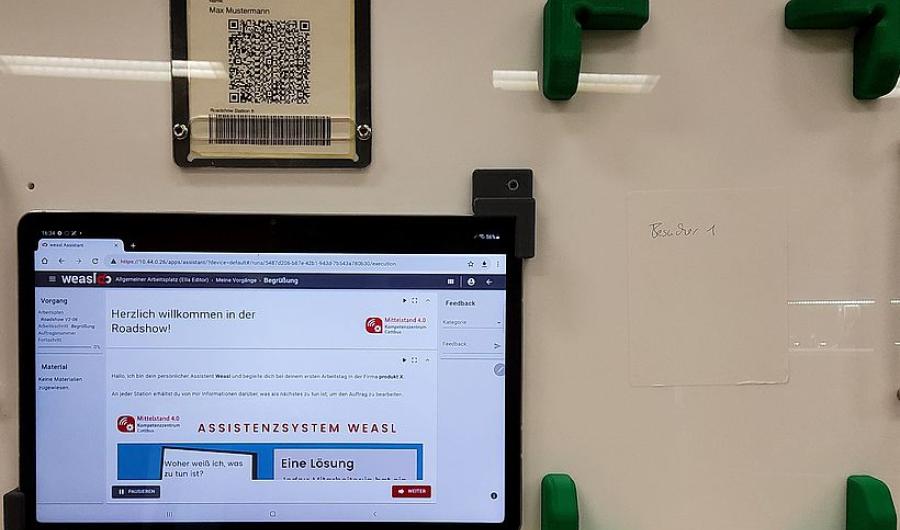

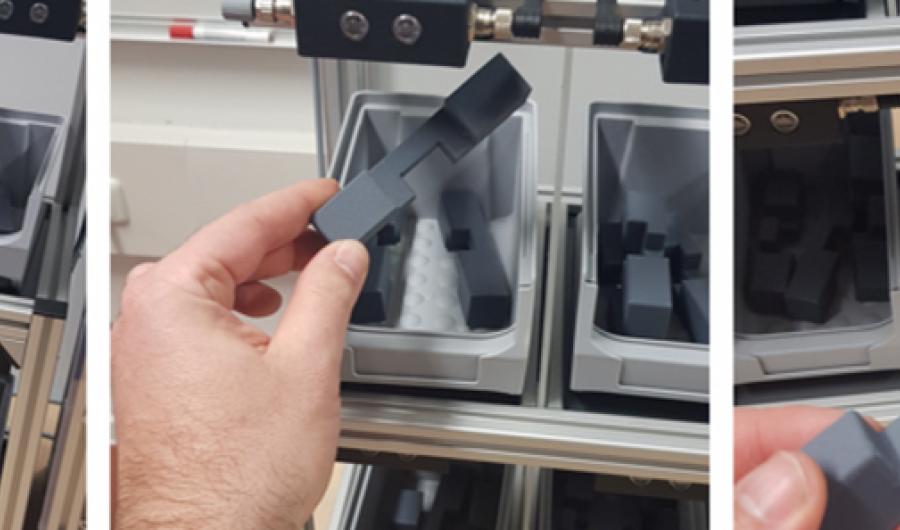

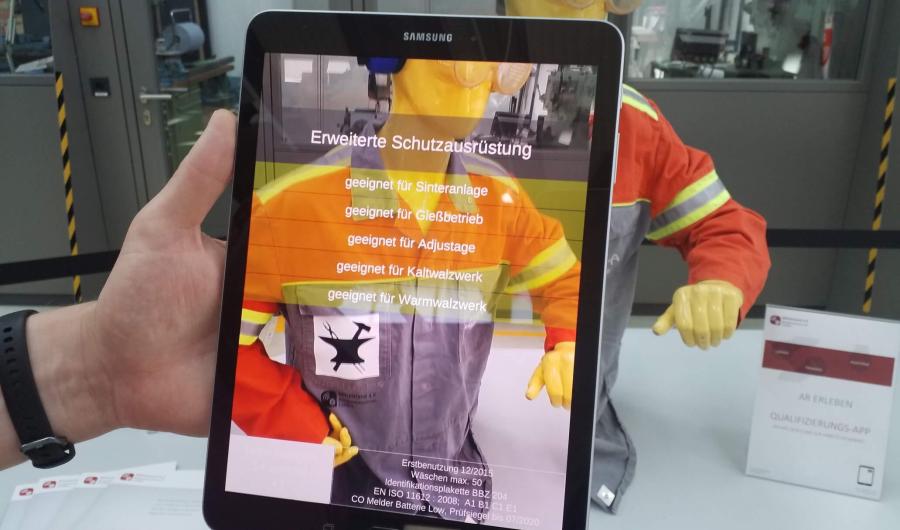

The demonstrator can be tested directly at the company and be easily integrated into the existing infrastructure. This way, companies see directly the benefits of digitization in a low-threshold way and train their employees on modern technologies.