Self-learning conveyor system for energy-efficient bulk material transport

Bulk solids represent the most widely transported main material and, due to their complex behavior, present great challenges for plant design. Precise and thoughtful planning as well as the experience of the designer are essential in the construction of economically well bulk handling plants. However, since a test phase with the actual bulk solids is useful during design, this is not often possible with existing plants.

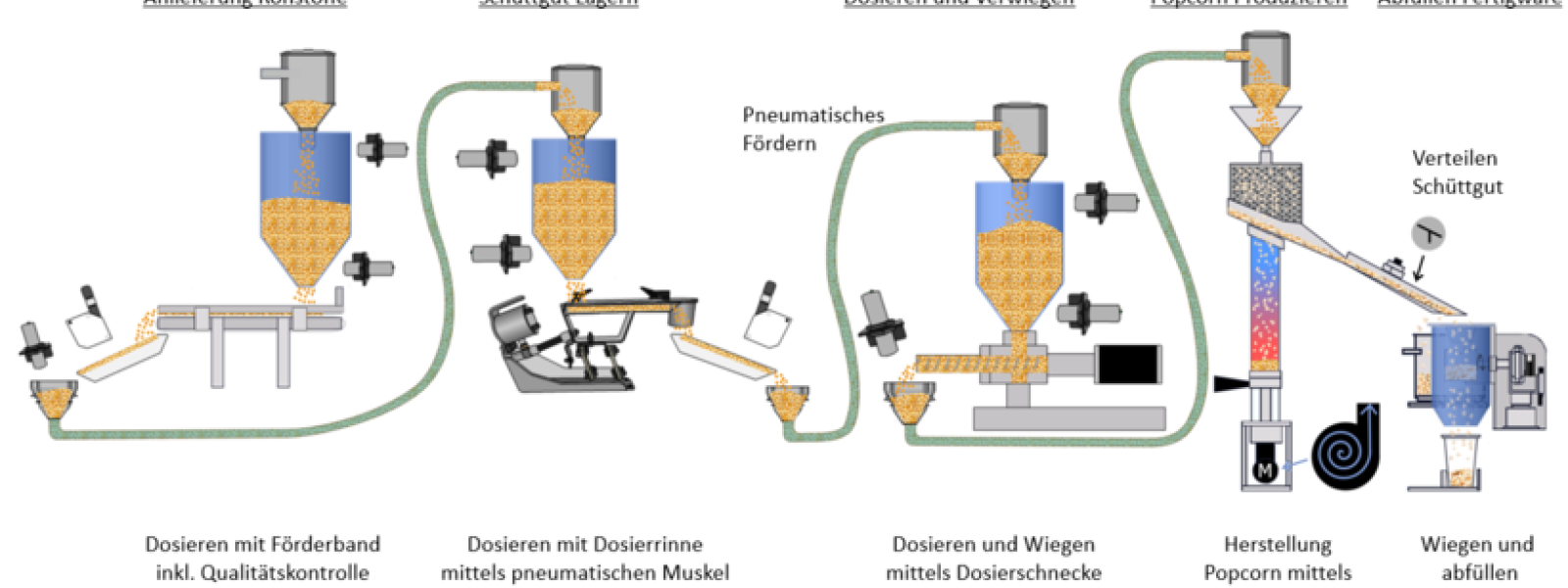

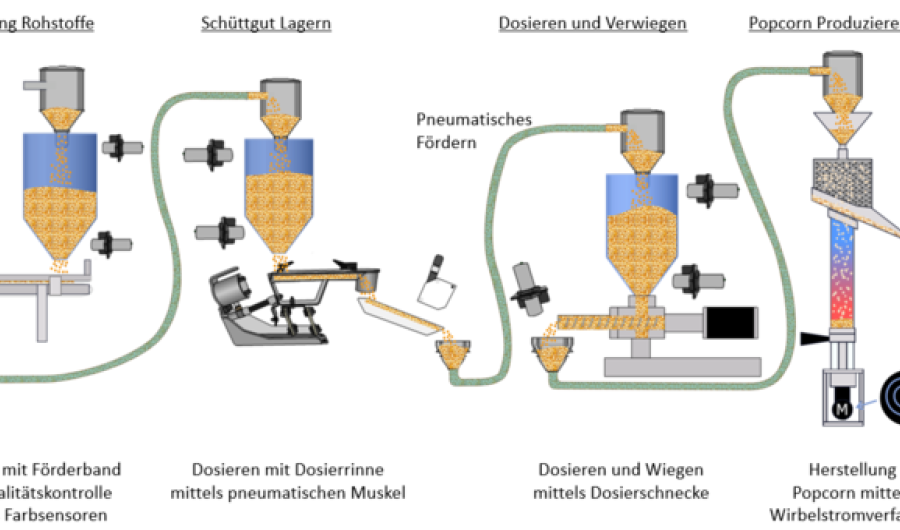

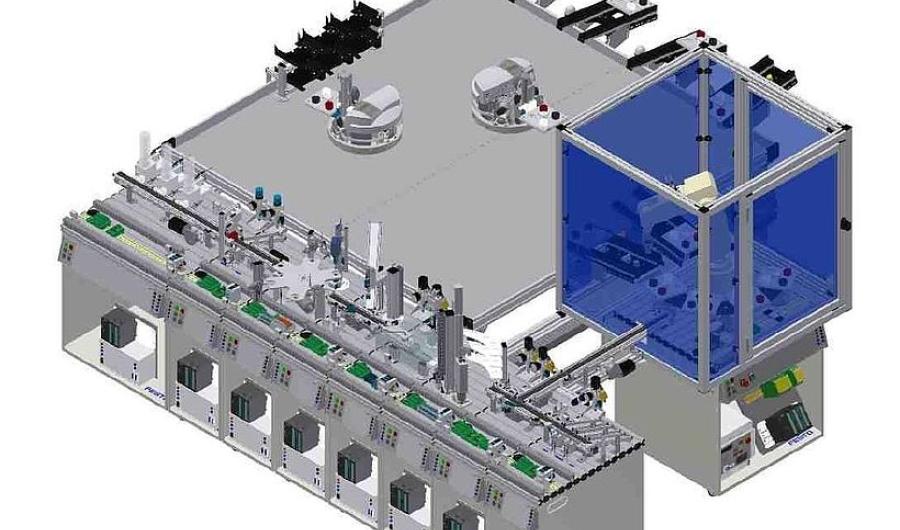

SeLFeeS, the test and experimental environment using the example of "corn" with the final product "popcorn", supports many goals by processing bulk solids in different steps. Based on realistic tests and immediate evaluations, prototypical applications can be quickly implemented and ideas derived first-hand.

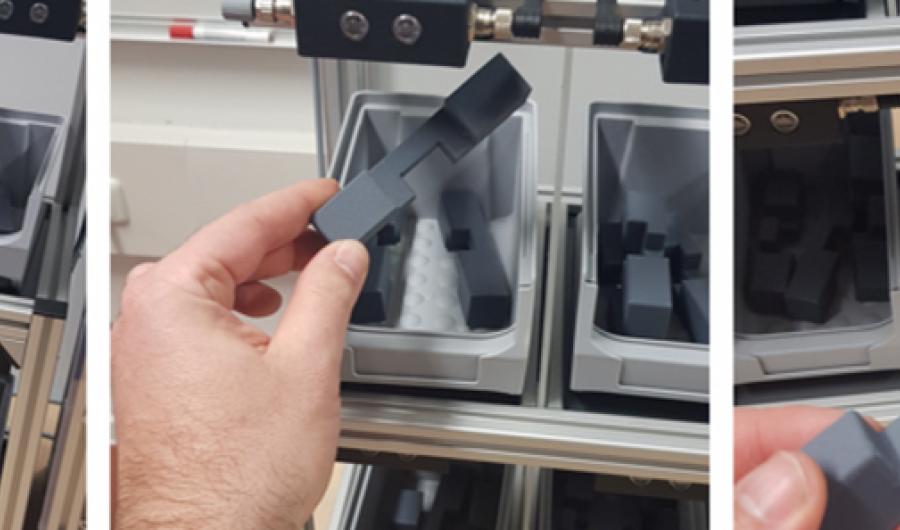

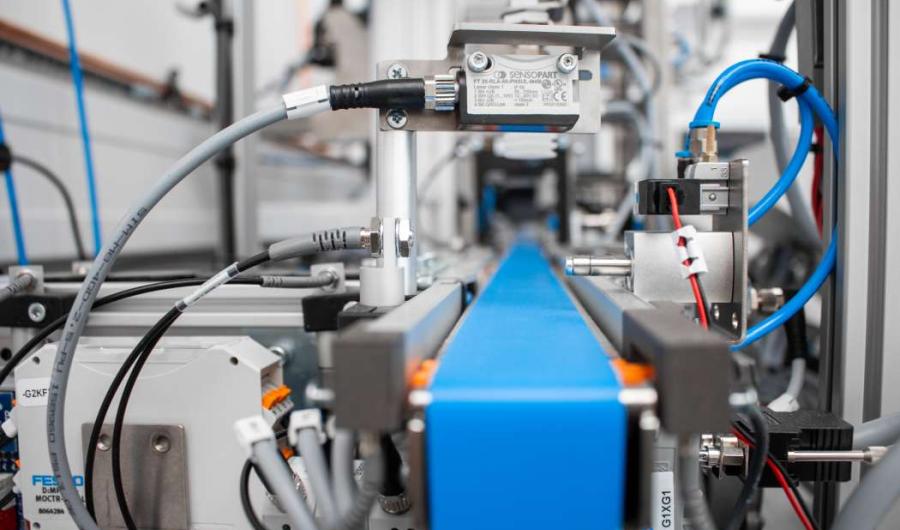

The system consists of several stations connected by conveyor belts and a dosing screw at the end. Quality assurance of the bulk material is performed by means of color sensors, camera technology and load cells. Eddy current and heated air jets are used to turn corn kernels into popcorn.

The interconnected production and logistics process of Selfees shown is representative of a large number of processes frequently encountered in the food and feed, pharmaceutical, cosmetics, chemical and plastics industries.

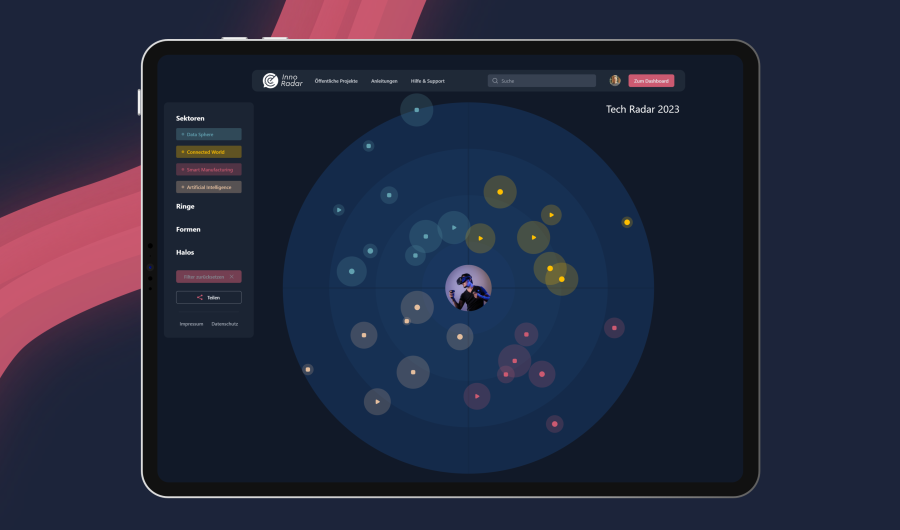

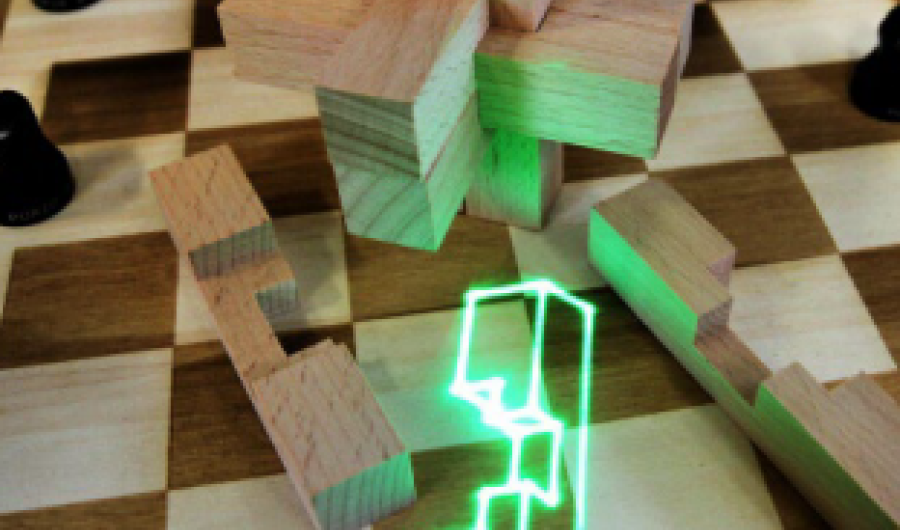

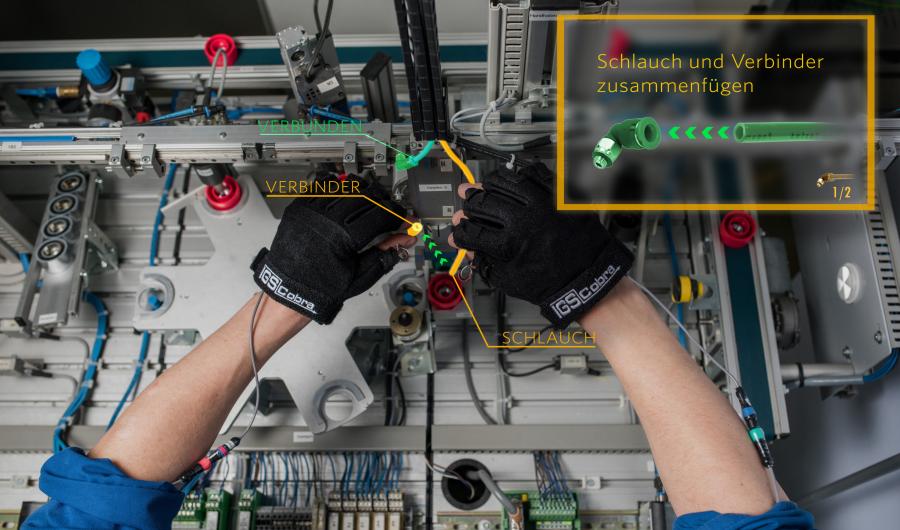

Through a modular design and various extensions, SeLFeeS also offers the ability to develop and evaluate AI applications, as well as quality measures for monitoring from raw material to finished product.

Where can you access this demonstrator?

Hub Wildau. At the University of Applied Sciences Wildau

Technical University of Applied Sciences Wildau; Hochschulring 1; 15745 Wildau