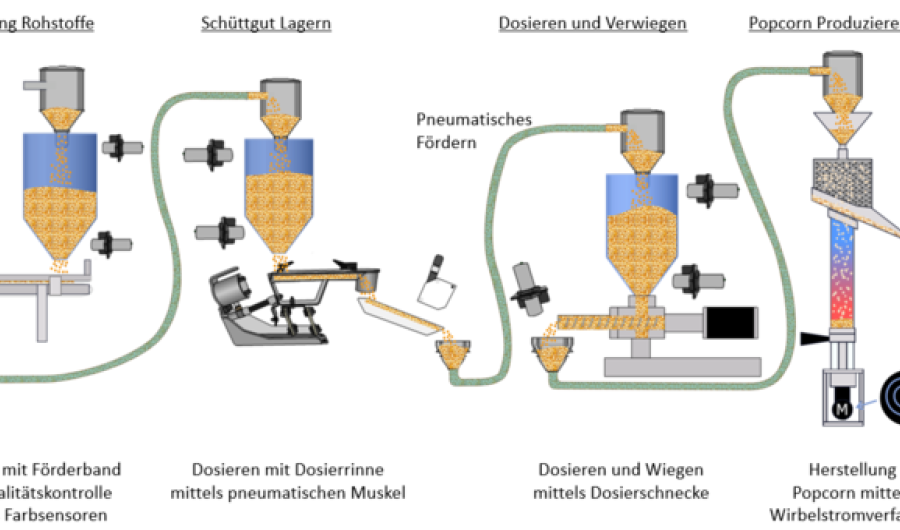

Digital upgrade of existing plants - making older machines and plants fit for networked production

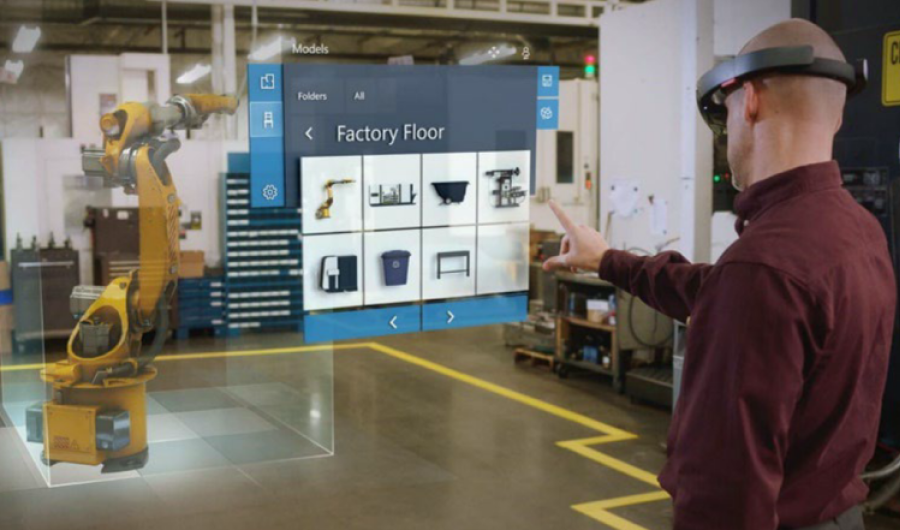

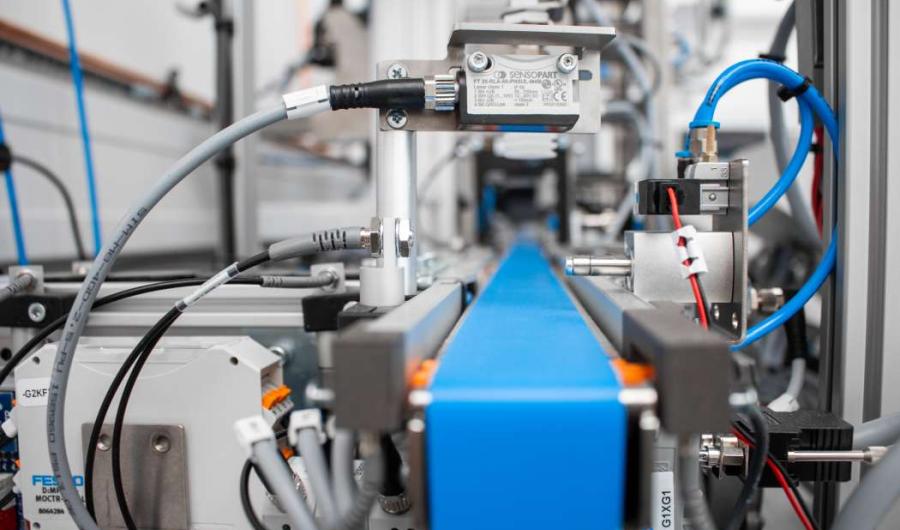

In the course oft he advancing Industry 4.0, intelligent networking of machines and processes in a changing, competing environment, retrofitting of old and proven machines is often pursued.

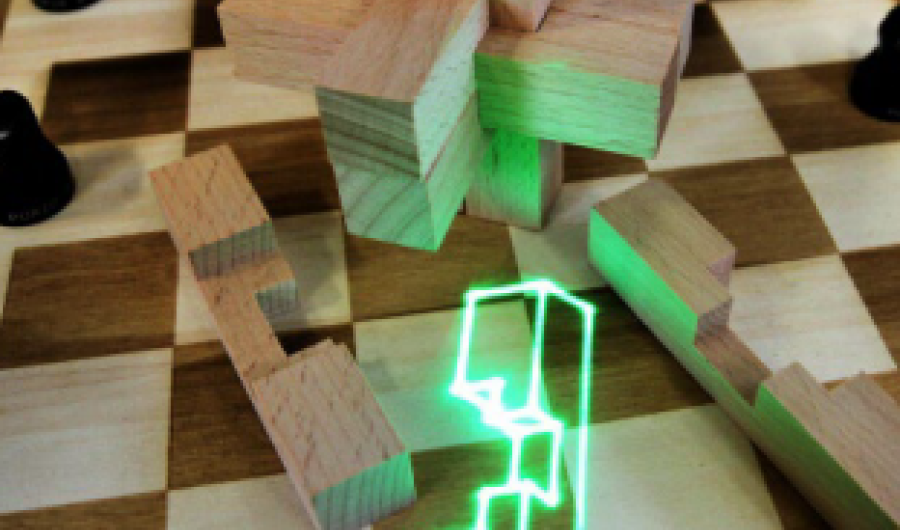

Using the example of a drilling machine, the once analogue machine can be integrated into the company´s digital network and controlled. In the process, a wide range of process and safety-relevant parameters, as well as temperatures, current and voltage are recorded, too.

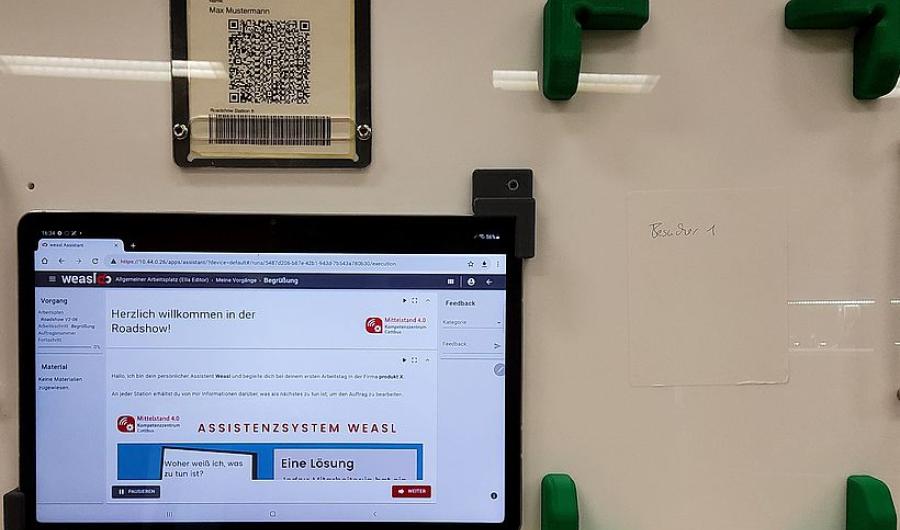

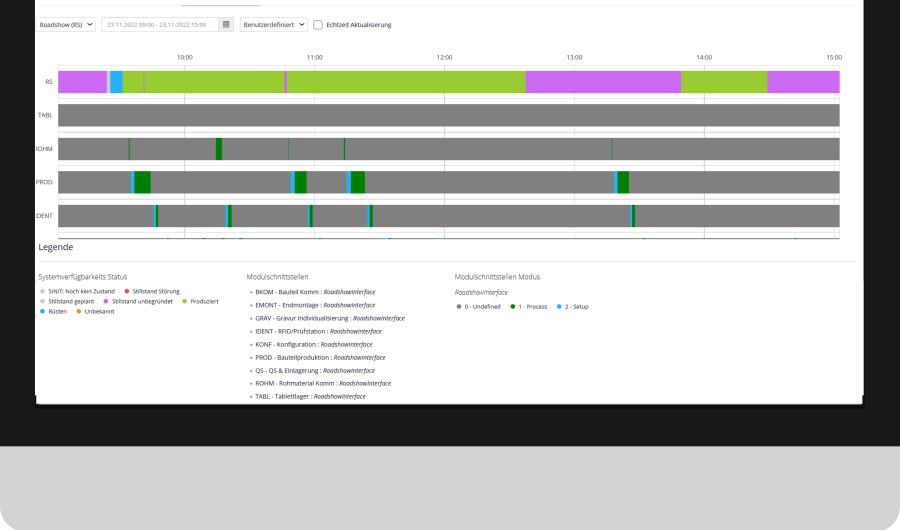

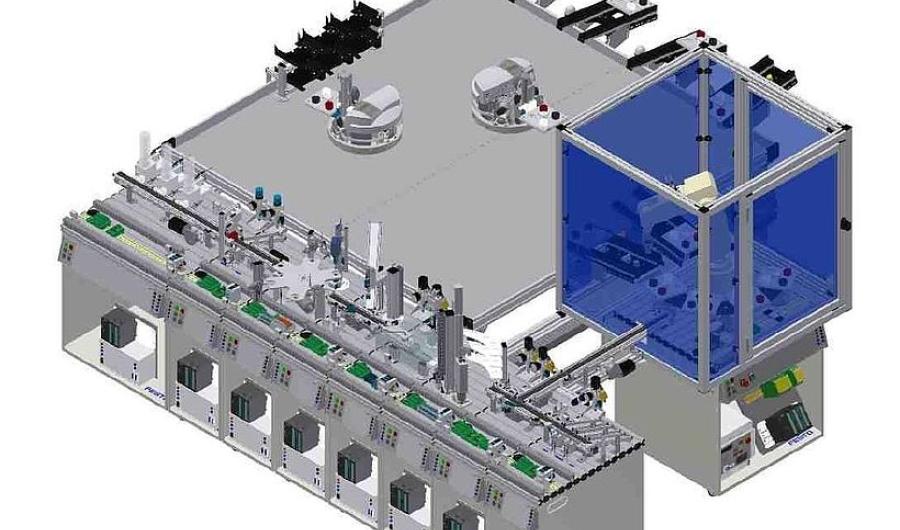

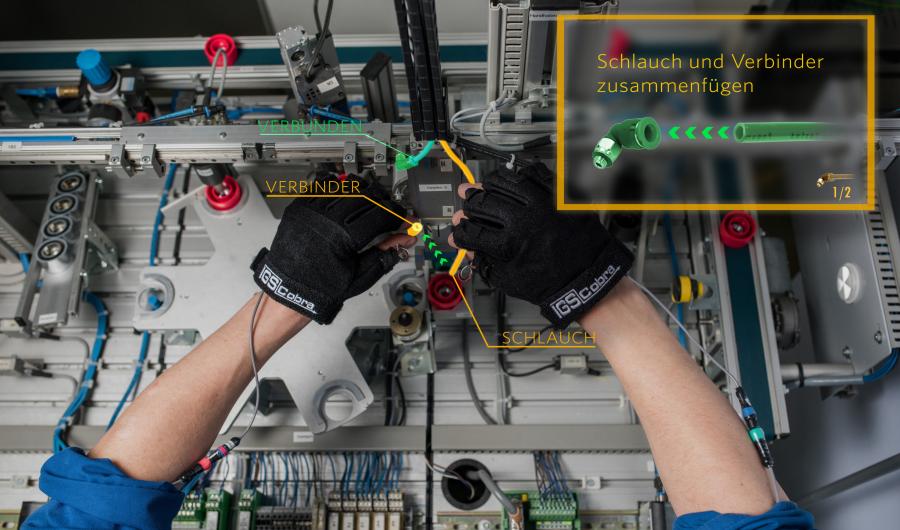

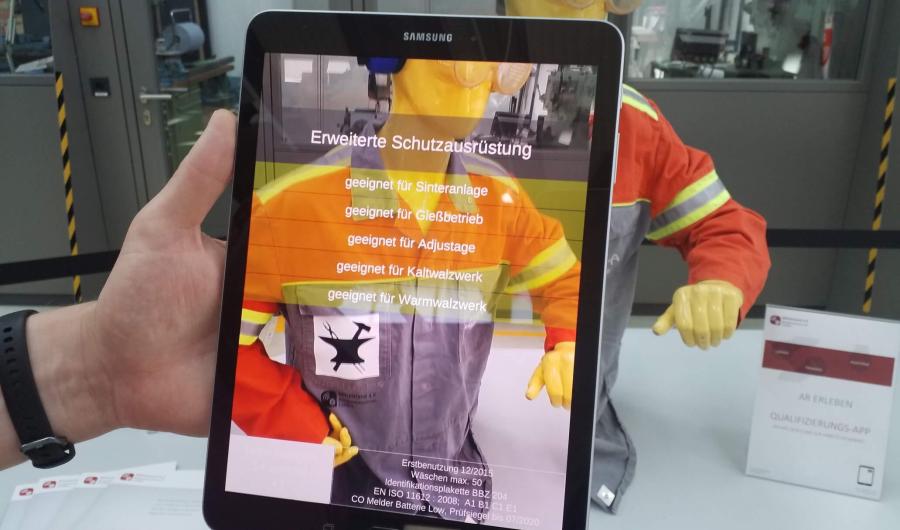

Various advantages result from intelligent networking for machine operators: old machines can be integrated and monitored remotely. Individual steps can be better coordinated and the utilisation oft he machine can be better planned. The integration of a user-specific assistance system can increase efficiency and productivity. Predictive maintenance measures, early detection of wear and maintenance intervals are also recorded and mapped individually fort he operation by means of process data.

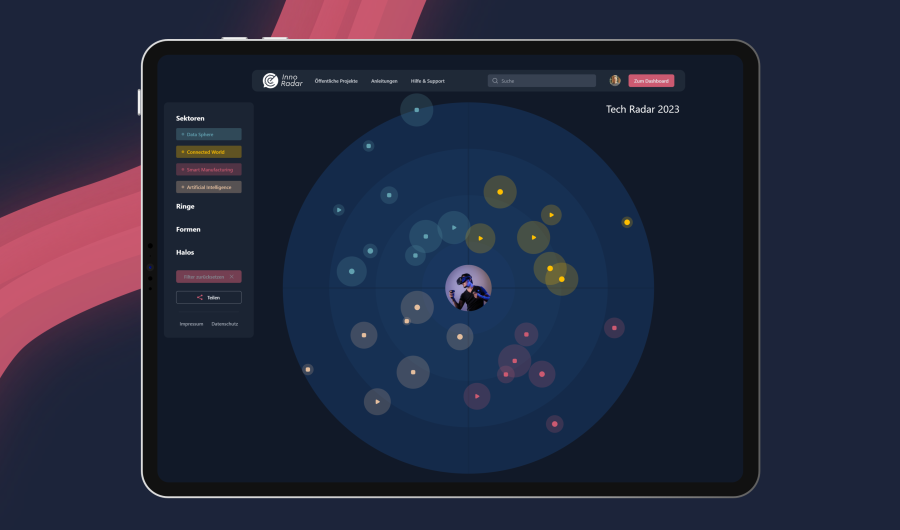

Technologies: Digtial Twin Technology, image processing, AR, sensor technology, measurement control system

Used for Conventional machines by retrofitting individual solutions

Where can you access this demonstrator?

Hub Wildau. At the University of Applied Sciences Wildau

Technical University of Applied Sciences Wildau; Hochschulring 1; 15745 Wildau