Increased Productivity with the help of a software Bots

Robotic automation for custom LASER engraving and cutting

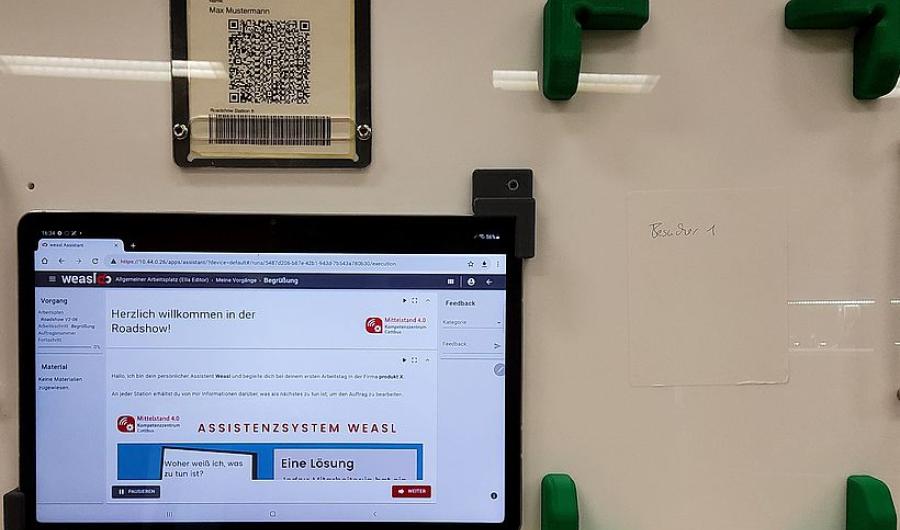

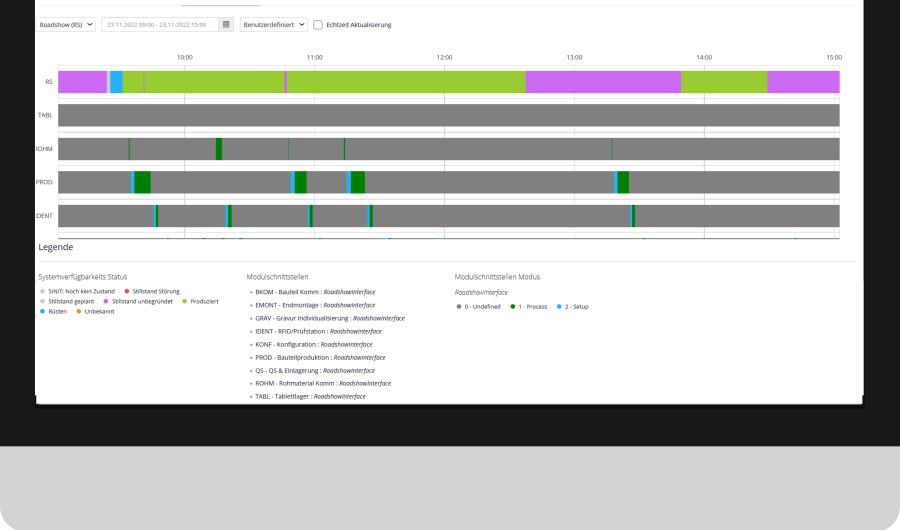

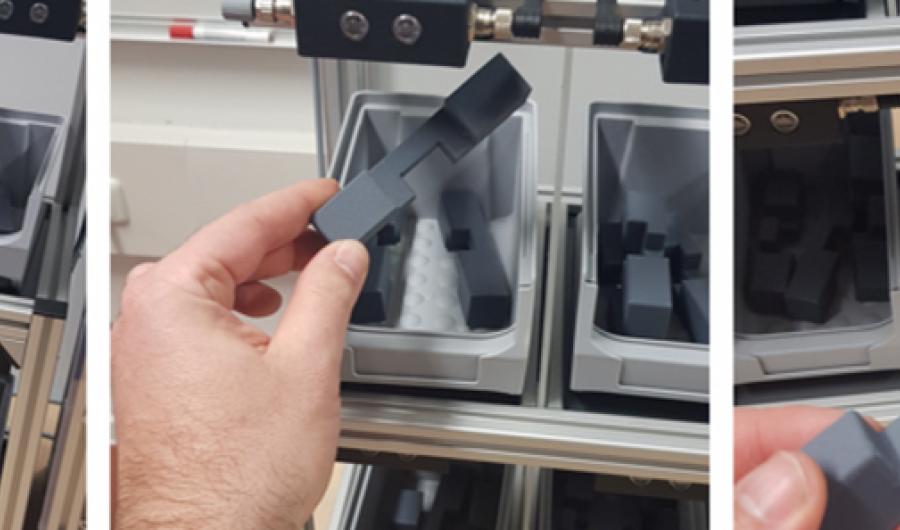

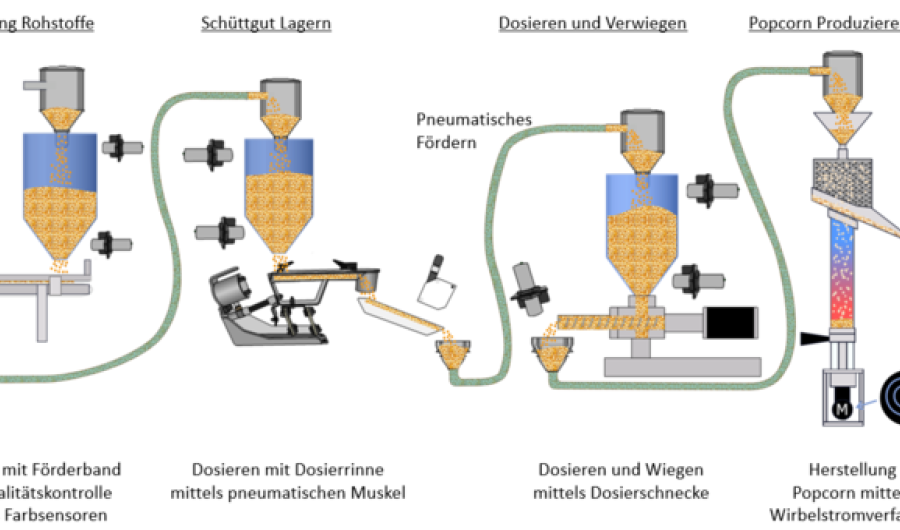

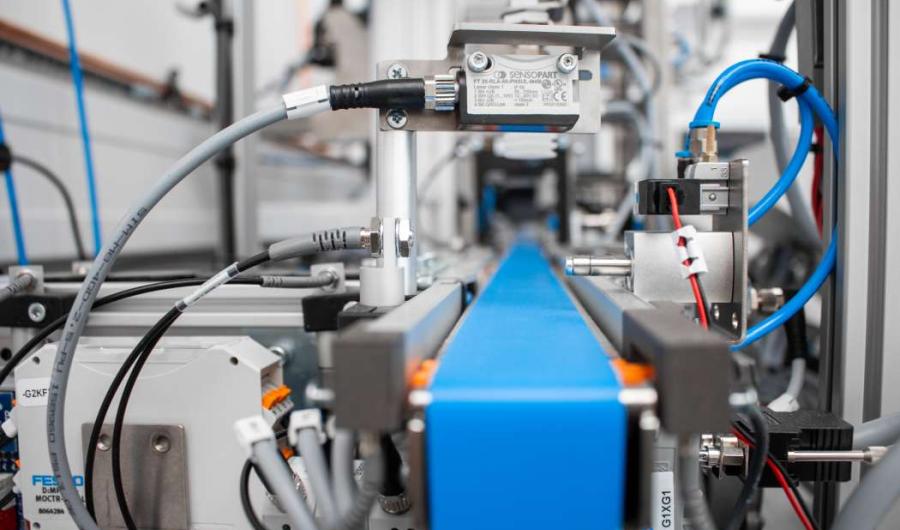

Individually created products are becoming increasingly popular, which raises the question for production companies of how to process a large number of orders quickly and easily. This can be accomplished with the help of a robot-based software solution. The hardware is prepared once for each production part, therefore the production worker only has to carry out a few steps for an individual product part in order to manufacture it. That way, production time optimization can be achieved. The Roadwhow uses the example of an individually engraved piece of wood to show how such optimization is achieved. With the help of a Poka-Yoke board, the orientation and position of the individual parts is predefined in order to reduce the error rate. The working process is now started with minimal information effort by means of QR code or database cross-linking, as there is a smart pre-programming. In addition, within this predefined information of the engraving area, the personalized text or the individual logo can be quickly and easily exchanged by software without any problems. The LASER engraving or LASER cut are extremely precise and fast techniques of opto-mechanics.

Technologies: Software robotics, database, LASER cutting, LASER engraving

Where can you access this demonstrator?

The demonstrator can be tested directly at the company and be easily integrated into the existing infrastructure. This way, companies see directly the benefits of digitization in a low-threshold way and train their employees on modern technologies.