Applying robotics in SMEs (SMErobotics)

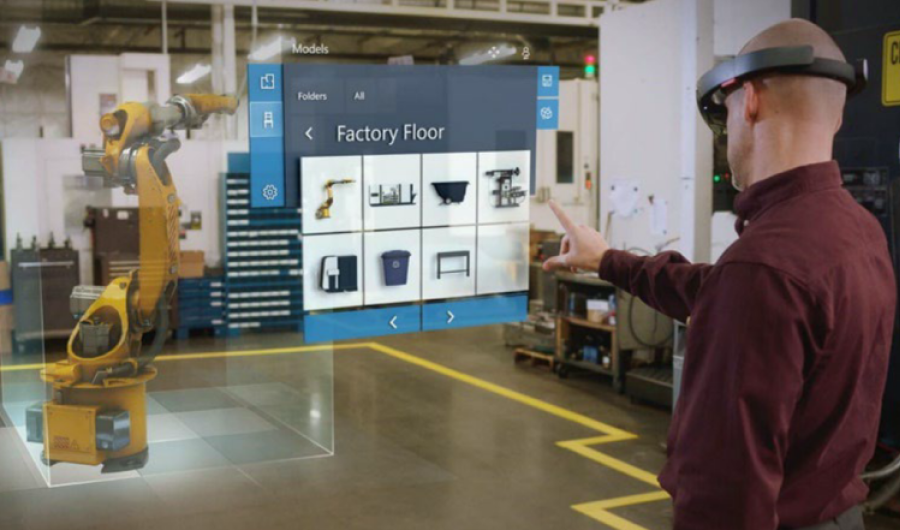

We understand, that SMEs face challenges of balancing a high number of variant counts and small batch sizes. This makes automation economically more difficult. Many activities remain manual, despite technical feasibility. The good news is that SEMrobotics can offer solutions by performing assemgly tasks that are difficult to implement with conventional technology. With our assistance, SMEs can optimize production processes and increase efficiency with our help.

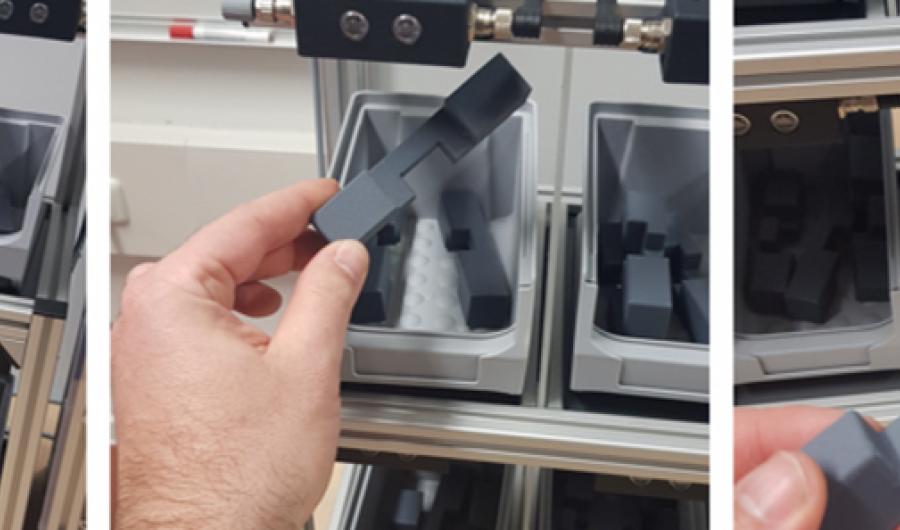

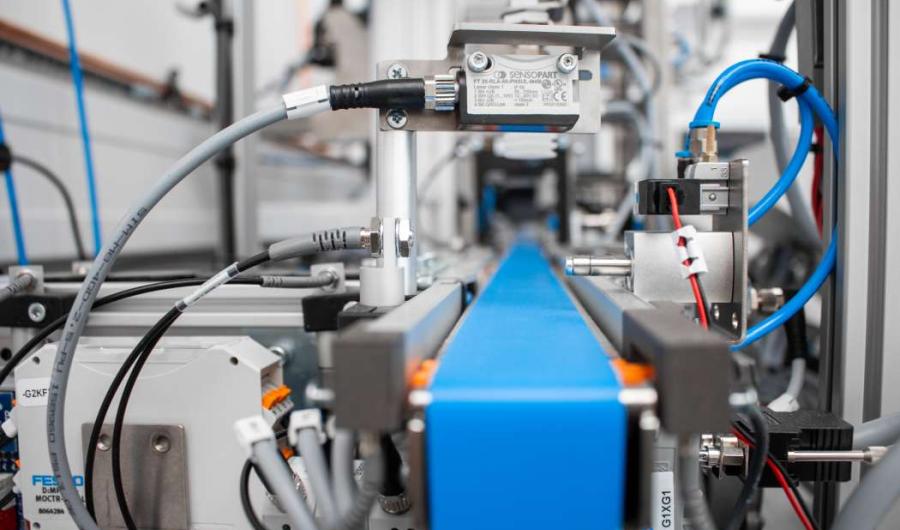

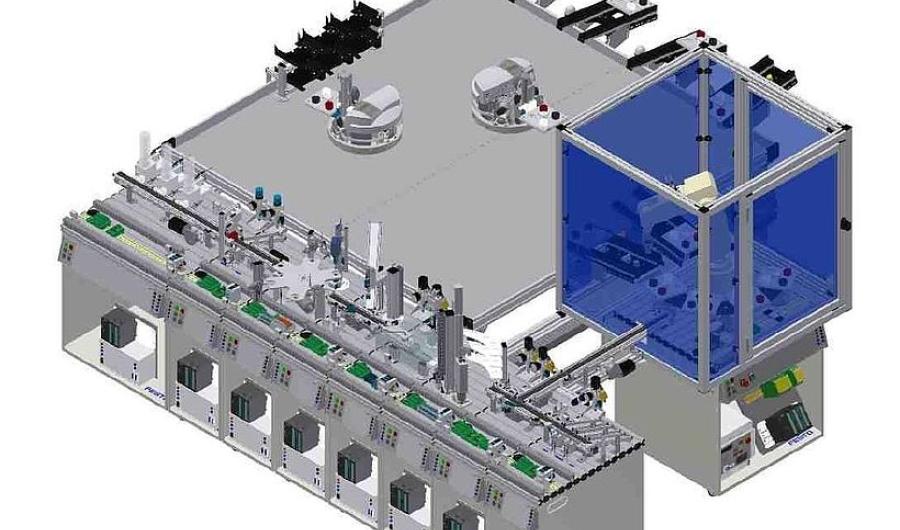

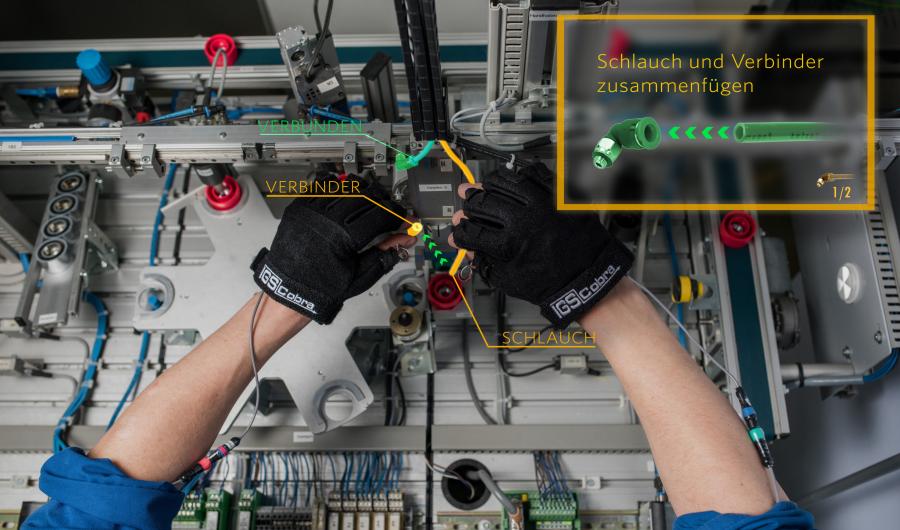

The assembly cell of SMErobotics research project enables flexible production of hydraulic valve segments in small batch sizes and allows flexible adaptation to future products. KUKA LBR iiwa robot with three different, interchangeable end effectors (two-finger gripper, electric screwdriver, pneumatically operated magnetic gripper) is used for this. The start of the production process and the programming of new variants take place via a graphical user interface directly on the robot cell.

Integrated Force-torque sensors in robot enable technically challenging assembly of hydraulic valves. In additon, inline quality controll of all assembled units is carried out by a robot.

This application detects component defects and reduces rework costs

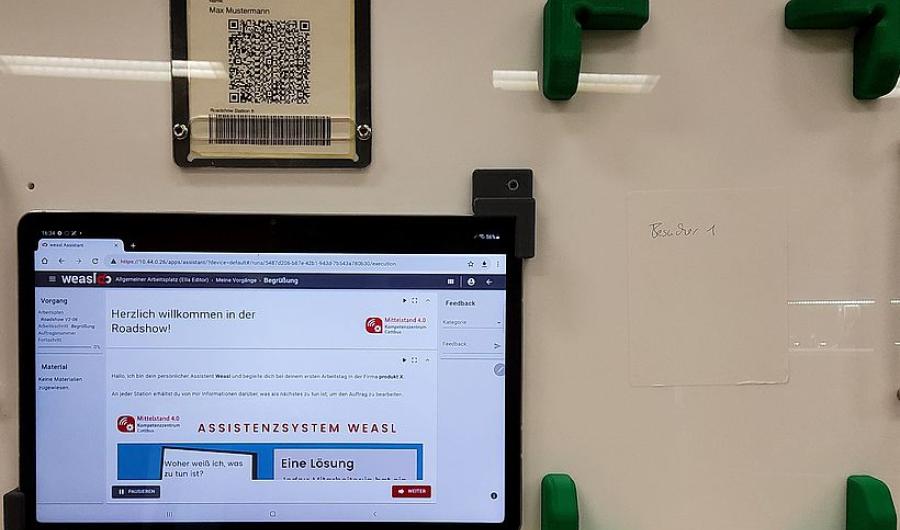

Frequent changes between different and new product variants are possible, thanks to the smart programming and operating system integrated in the cell. The system is easy to learn by operators with little knowledge in robotics and programming.

Businesses are welcome to visit the demonstrator at our model factory at BTU Cottbus

Technologies:

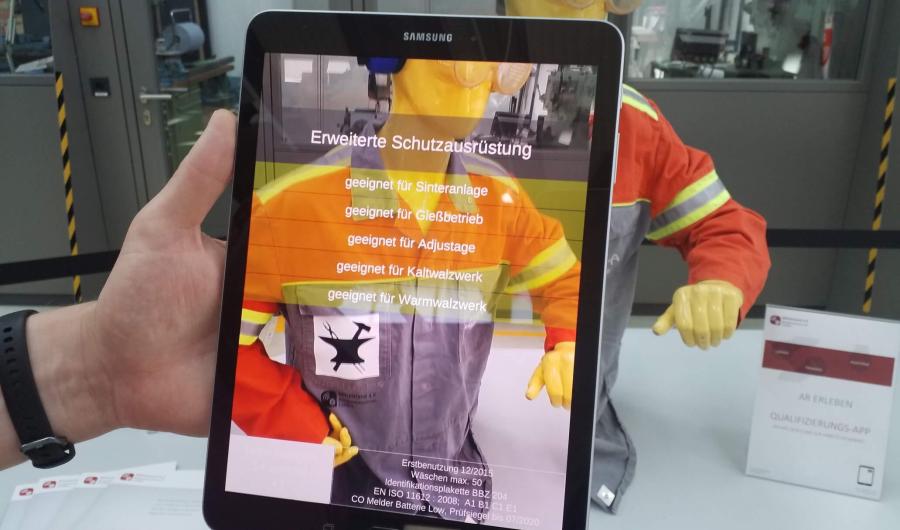

AI, digital twin technology, image processing technology

Where can you access this demonstrator?

Hub Cottbus. At the BTU Cottbus-Senftenberg, BTU Cottbus-Senftenberg; Siemens-Halske-Ring 14; 03046 Cottbus