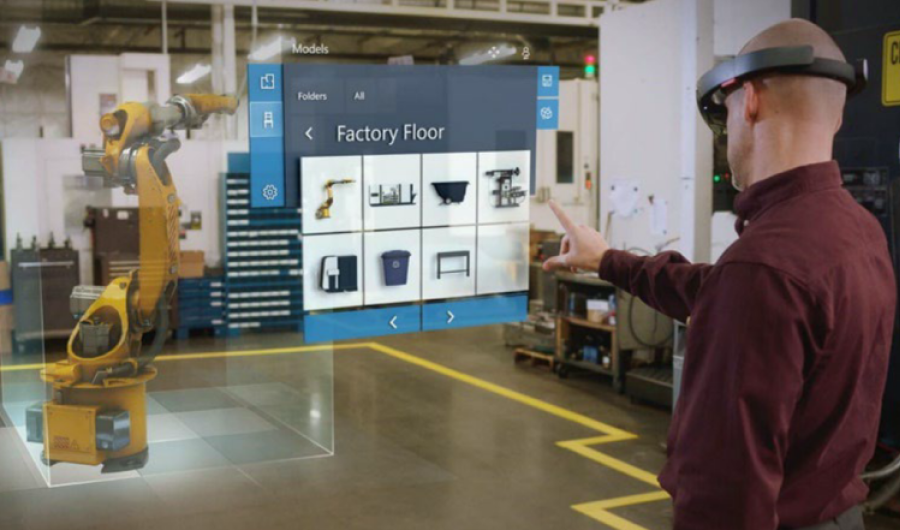

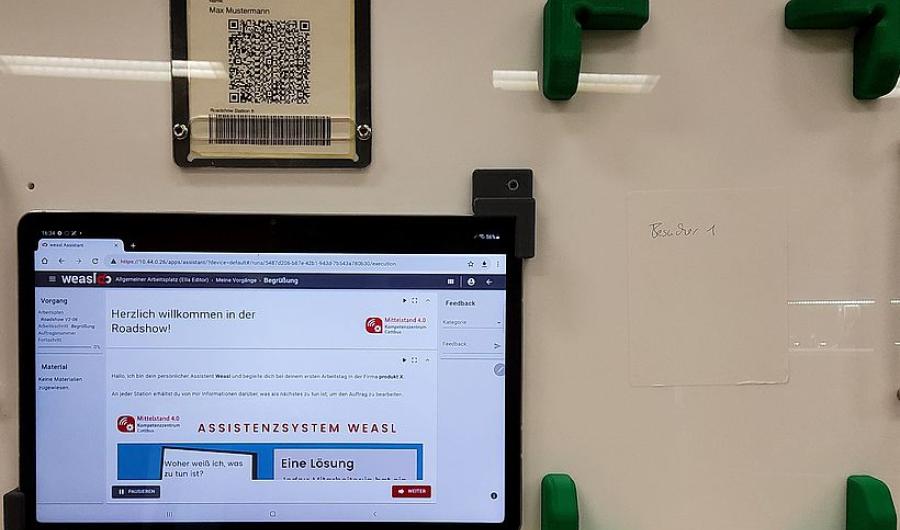

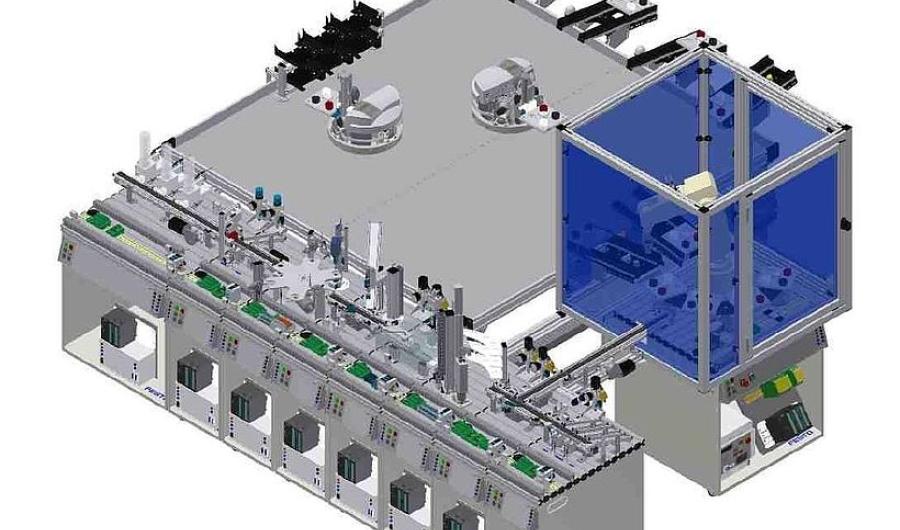

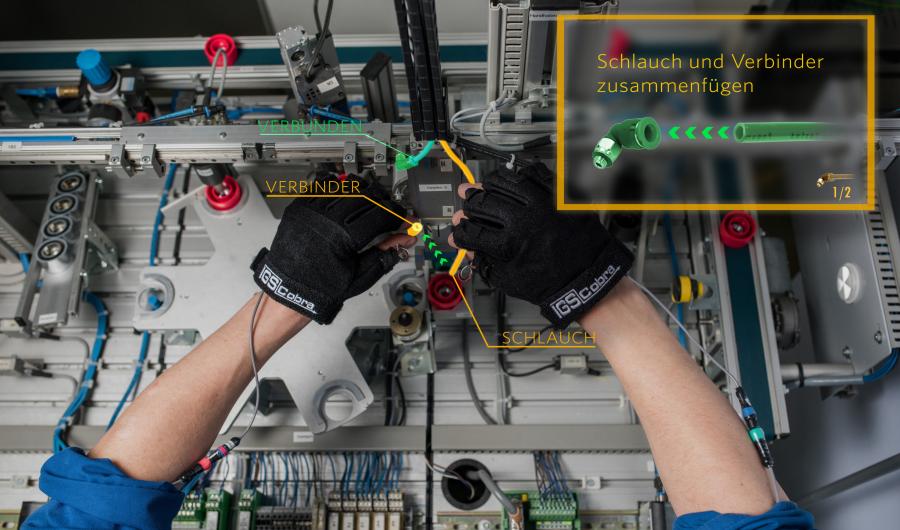

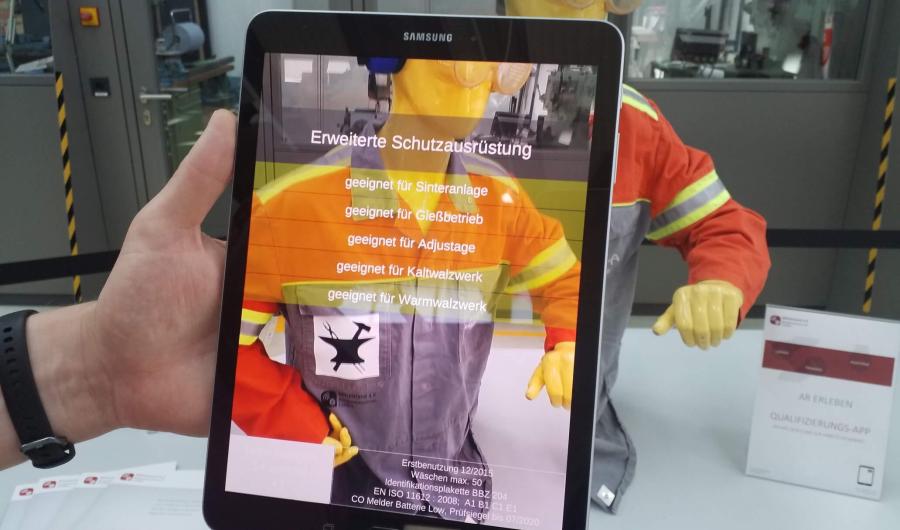

Demonstrators and testing infrastructure

What are the benefits of AI-connected quality control?

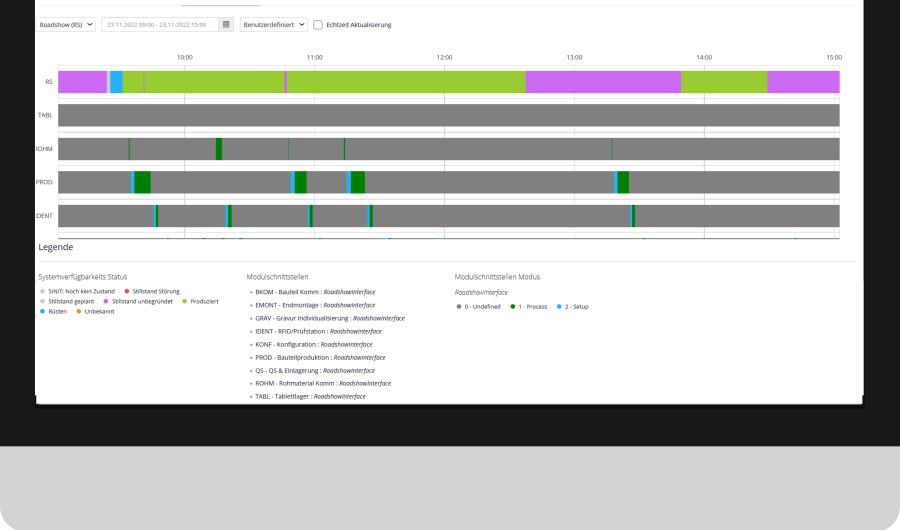

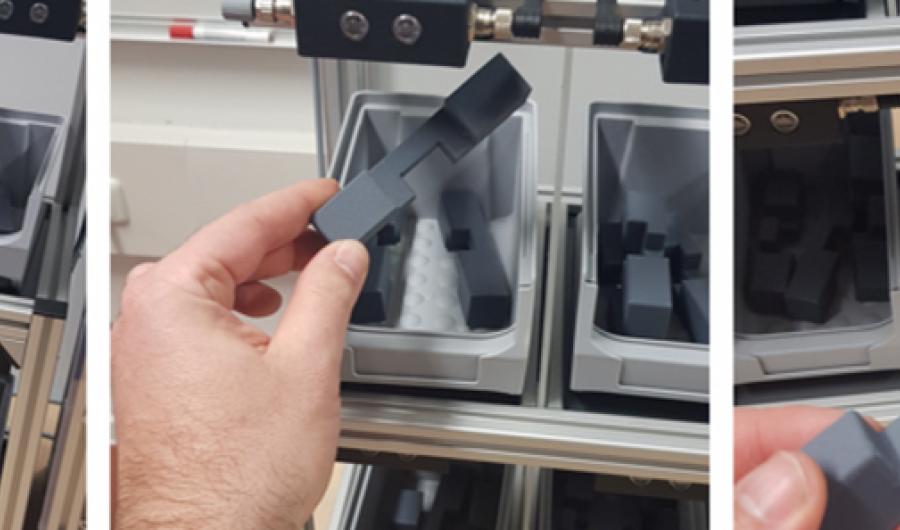

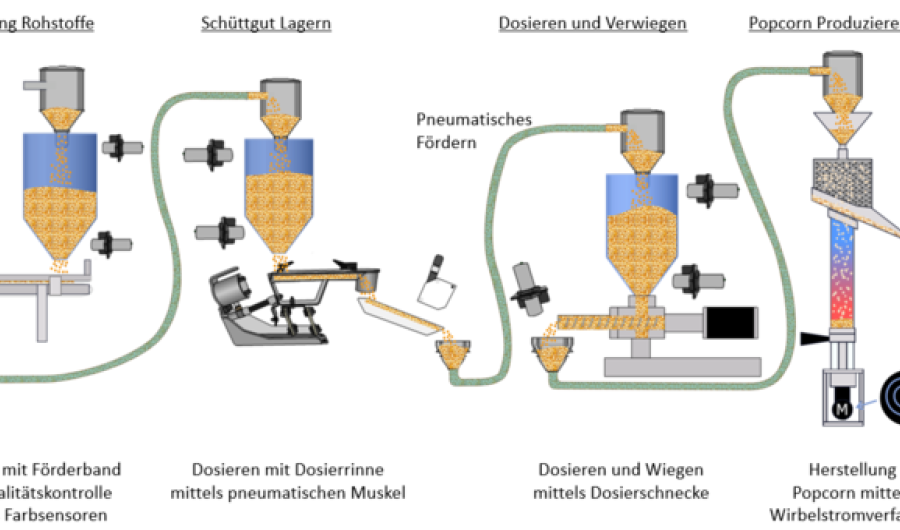

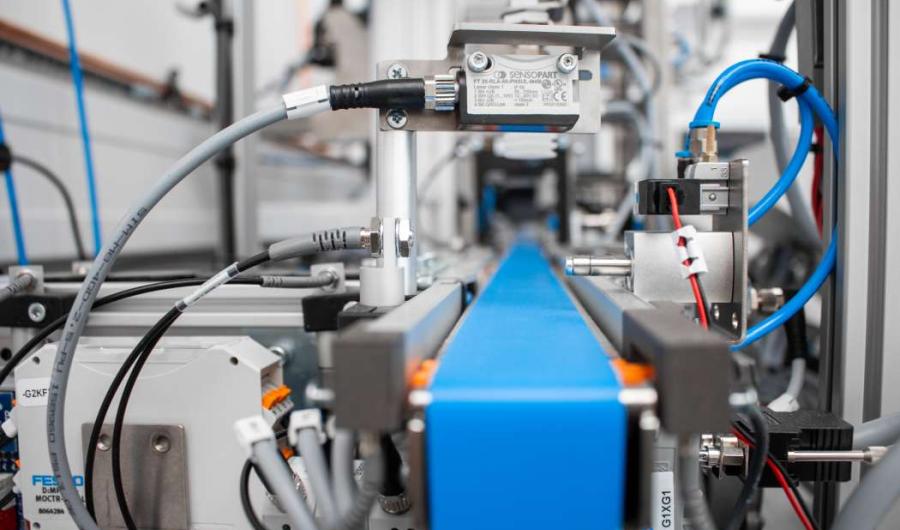

Can intelligent sensor technology help with maintenance? In our innovation centers (Modellhalle and Präsenzstellen) you have the opportunity to examine many exciting demonstrators and test them in a real environment. We can show you applications of automation, for production processes, workflows, in quality and control management, as well as in IT security, maintenance and material testing and much more. Have a look at our catalog and contact us if you are interested. We will be happy to advise you and support you in finding the right application for your company.