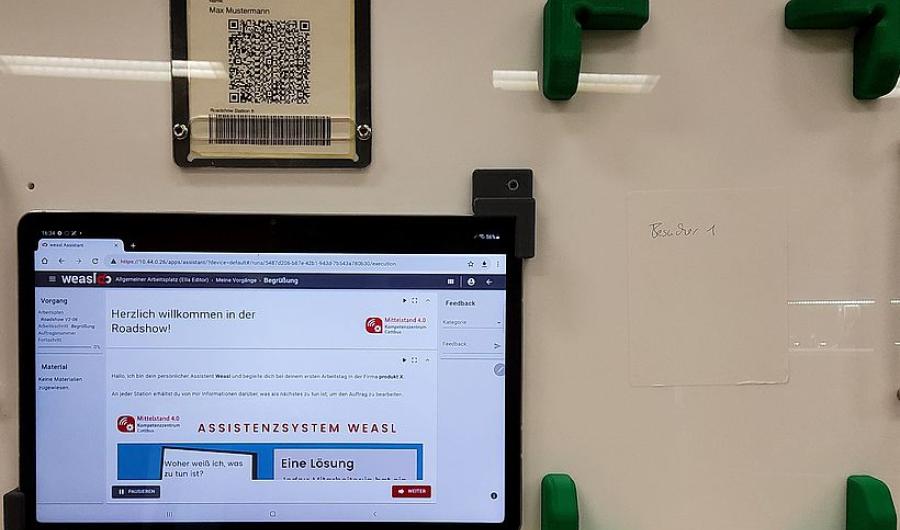

Product identification with RFID and energy monitoring.

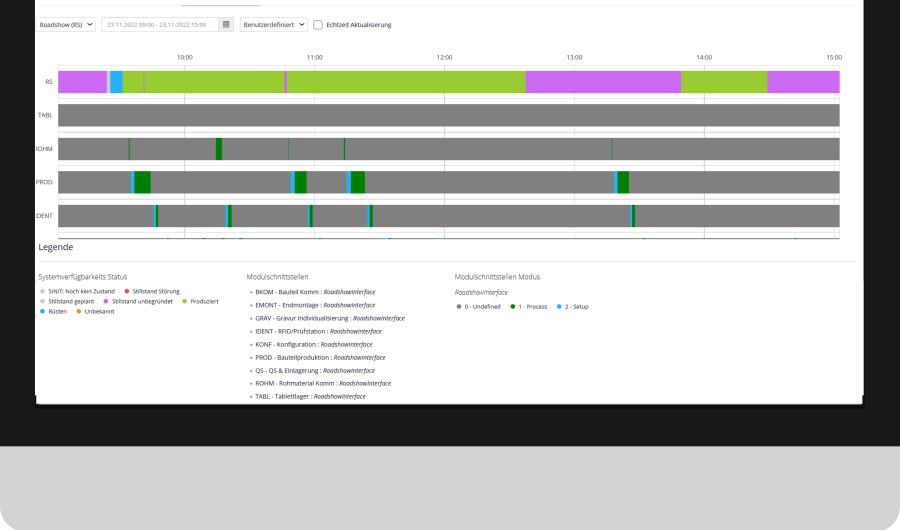

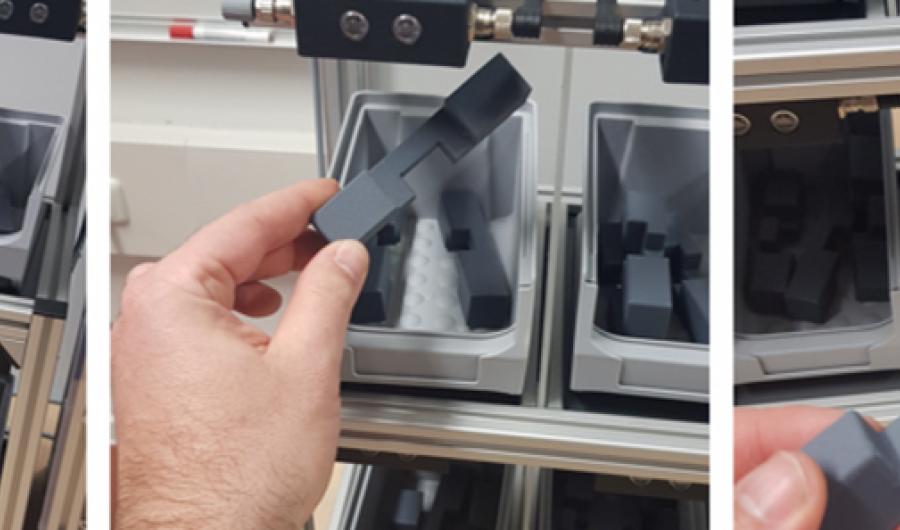

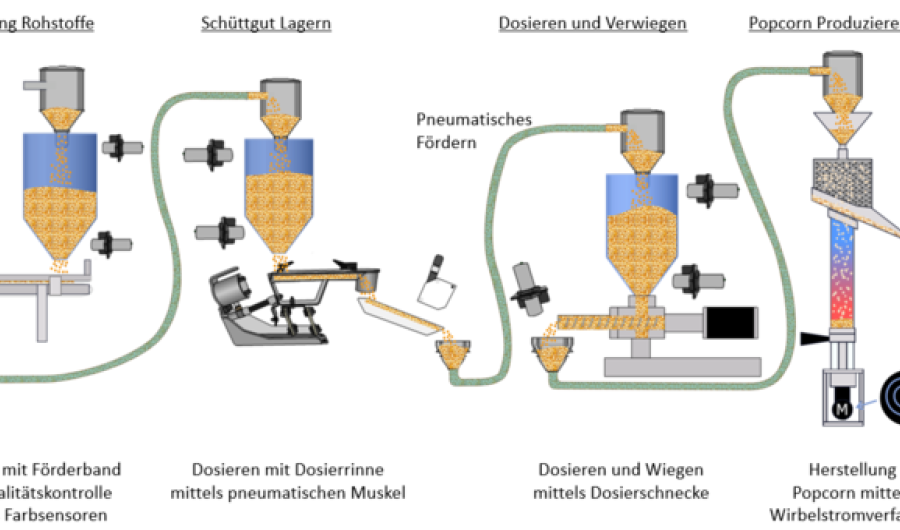

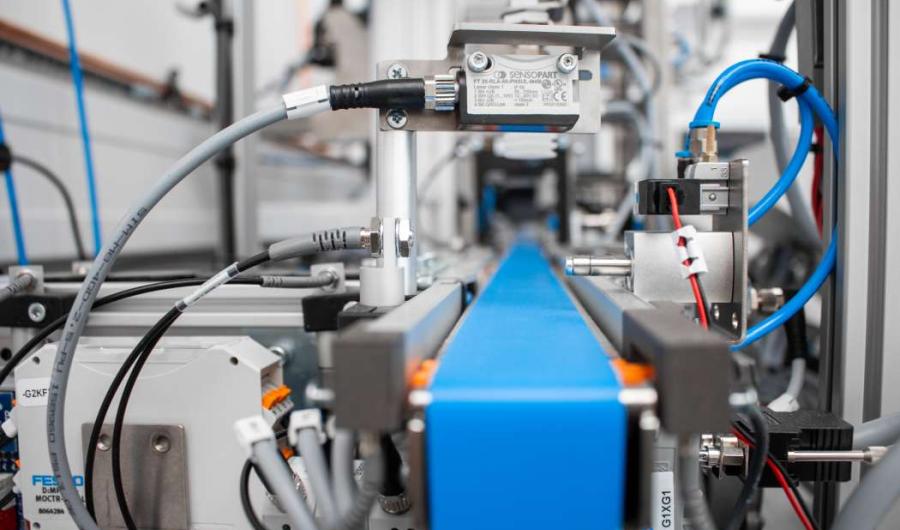

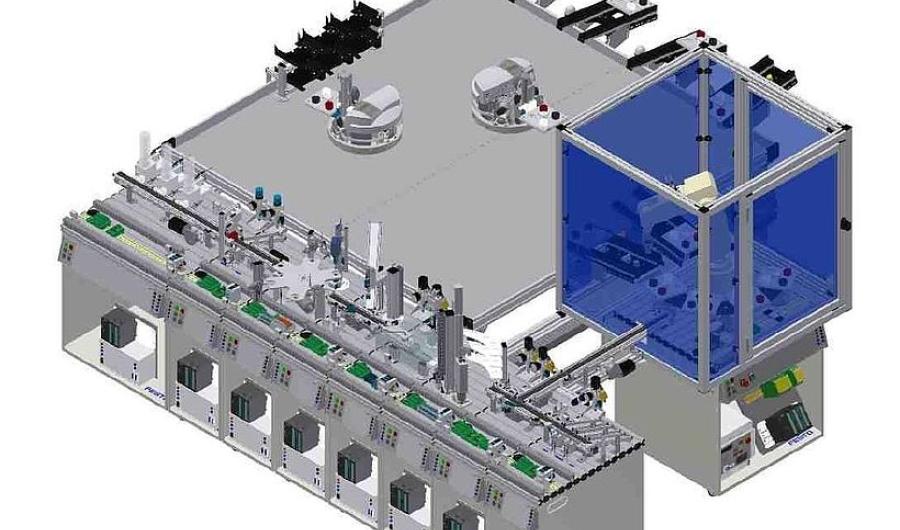

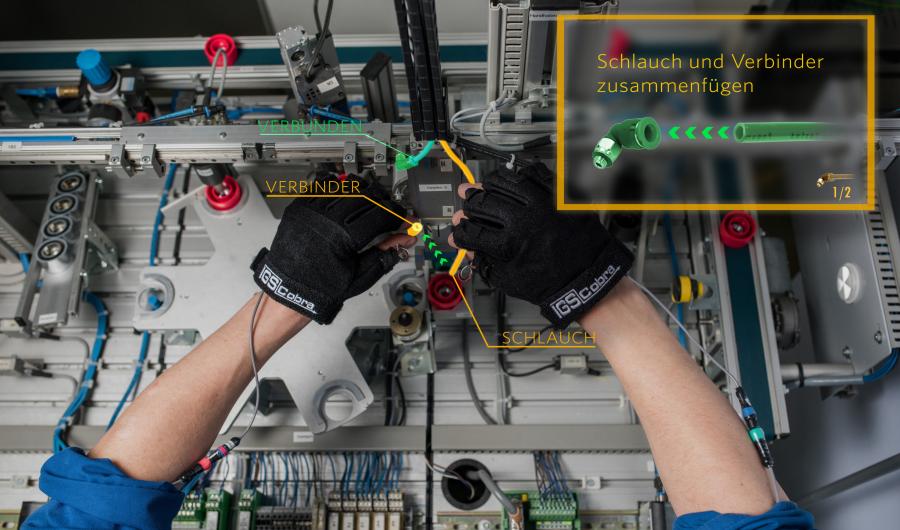

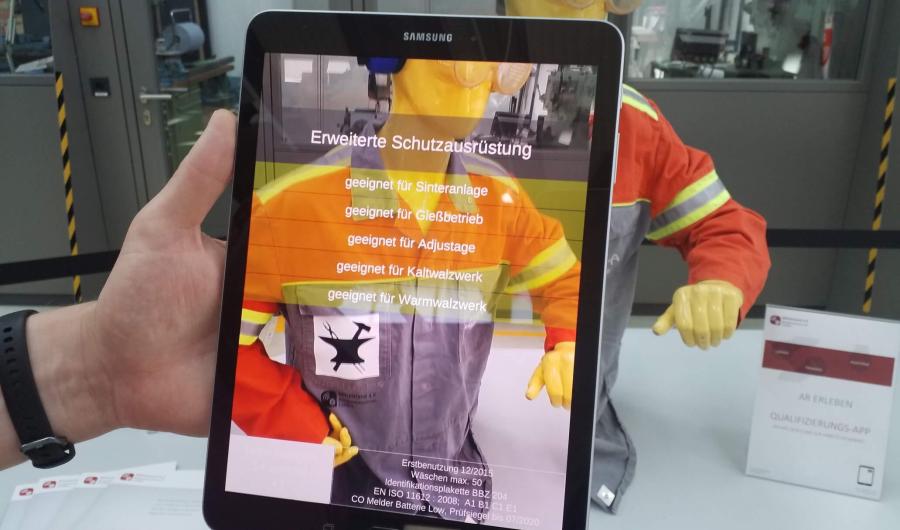

The challenge: The roadshow includes a product identifier that detects various failures during production. For example, a drop in pressure can cause malfunctions in pneumatically controlled elements. In addition to pneumatic data, energy values and data are also displayed, enabling an analysis of the machine's state. Preventive measures based on this data can reduce failures or maintenance intervals. RFID tags are attached to small parts to provide job and material condition information. The shadow board also enables visual pre-picking and helps identify missing individual parts.

The advantages and possibilities of this technology are its flexibility. Additional readout of energy data and values can be easily retrofitted to conventional machines and help with maintenance. This data provides information for energy savings so that ISO 50001 can be addressed. The traceability of small parts, essential for allocation in the production order, is realized with the help of RFID technology.

Where can you access this demonstrator?

The demonstrator can be tested directly at the company and be easily integrated into the existing infrastructure. This way, companies see directly the benefits of digitization in a low-threshold way and train their employees on modern technologies.