Digitizing manual assembly and prozesses

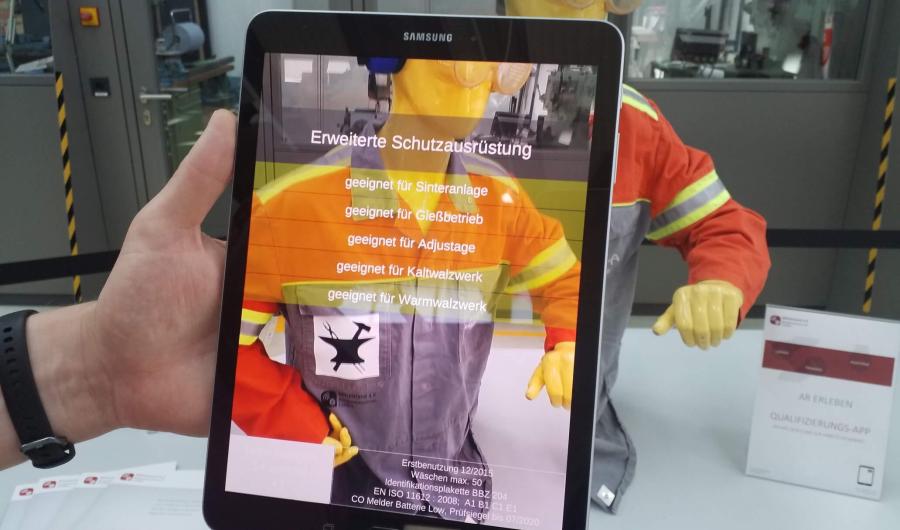

How can you transfer know-how effectively and efficiently in a high-paced schedule of SMEs while maintaining all operating processes?

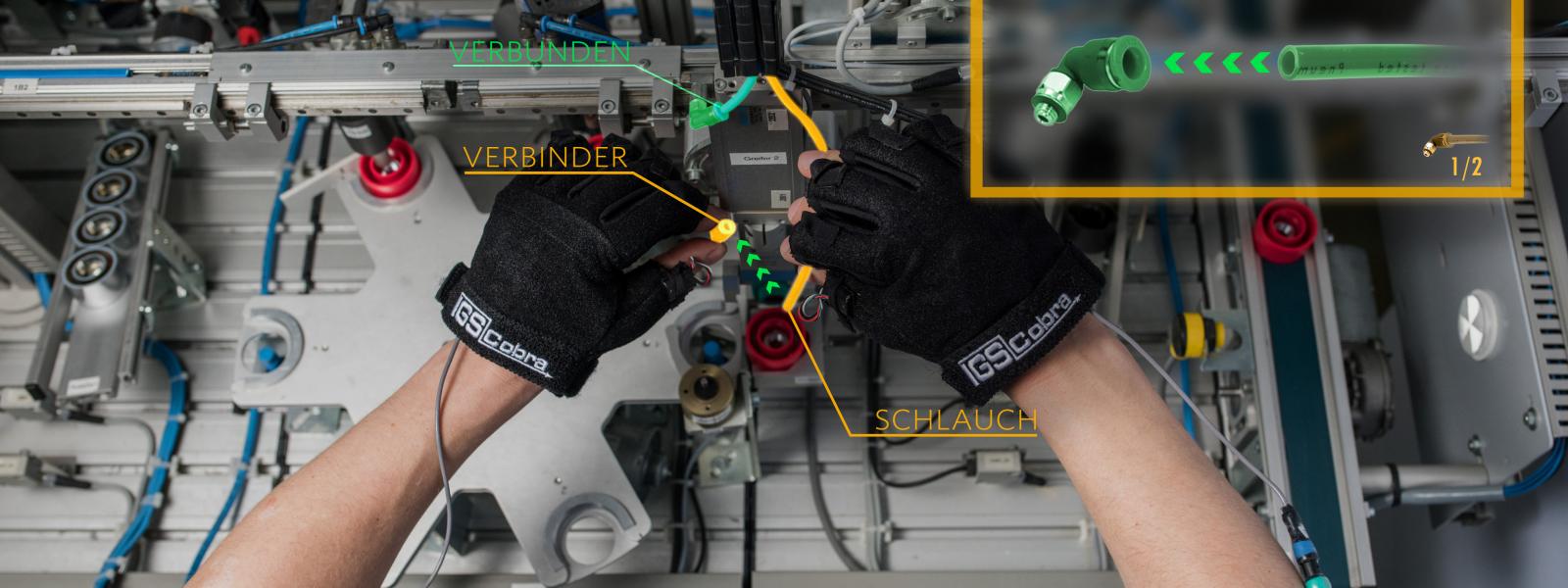

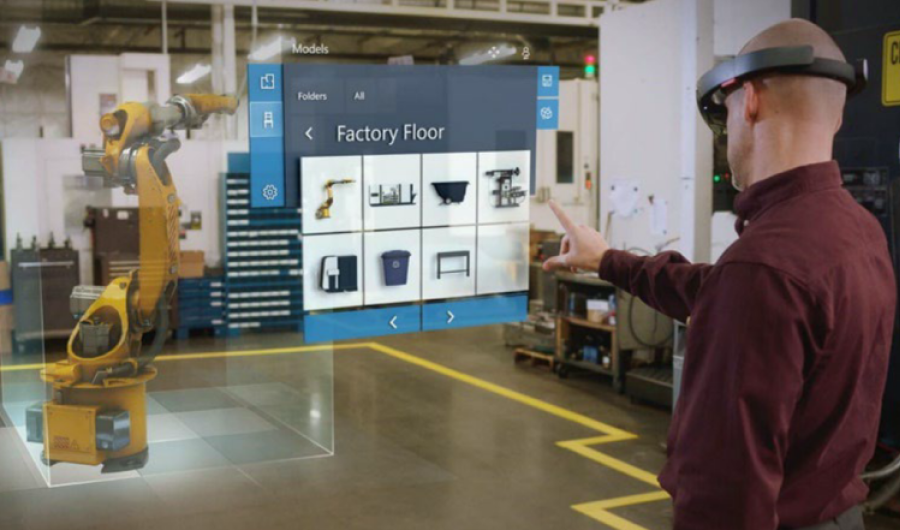

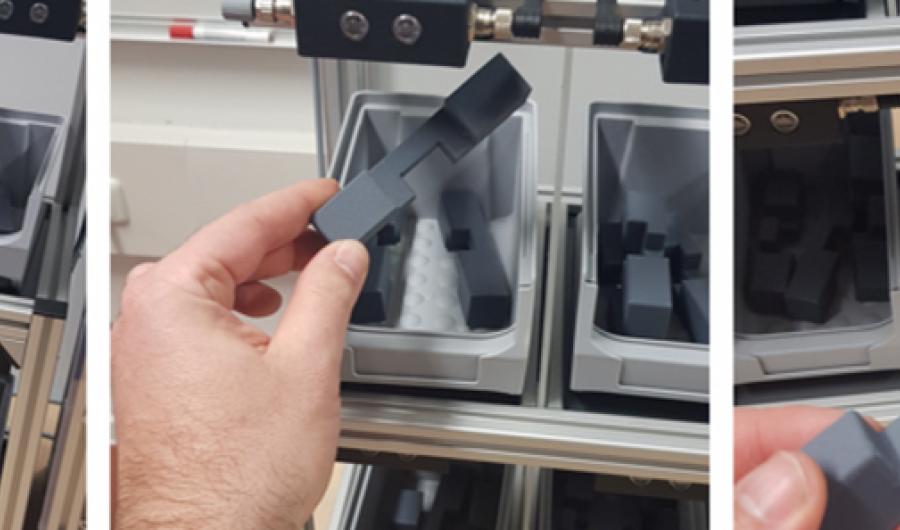

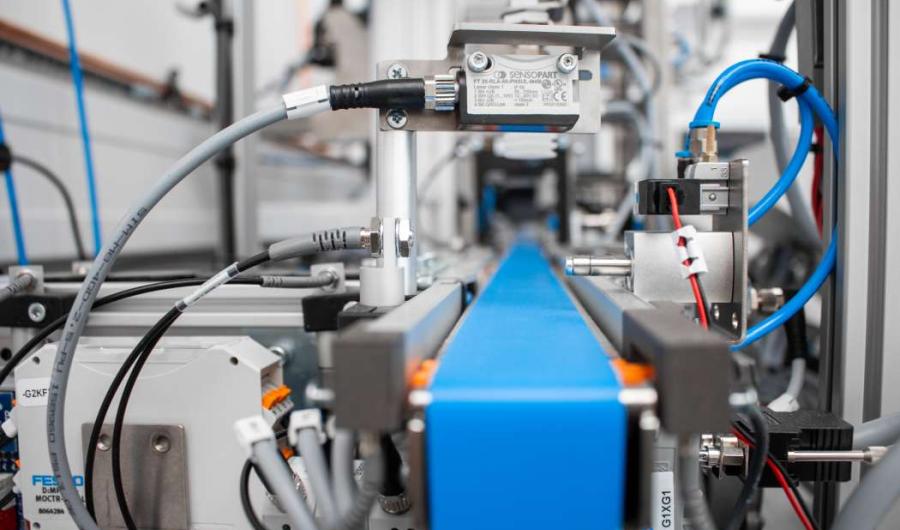

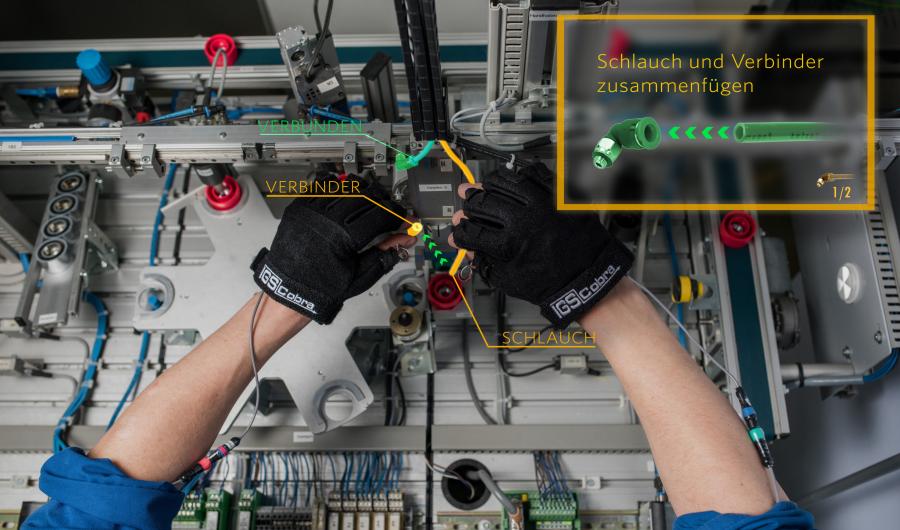

With the sensor data glove and its implemented help of an intelligent assistance systems (machine learning), employees at a manual assembly plant are provided with information and support in the learning process. This innovative approach is based on gesture recognition and enables targeted information supply while carrying out work in real time. IMU Inertial Measurement Unit acceleration sensors automatically recongnize and digitize individual steps and contribute therefor to faster and safer work.

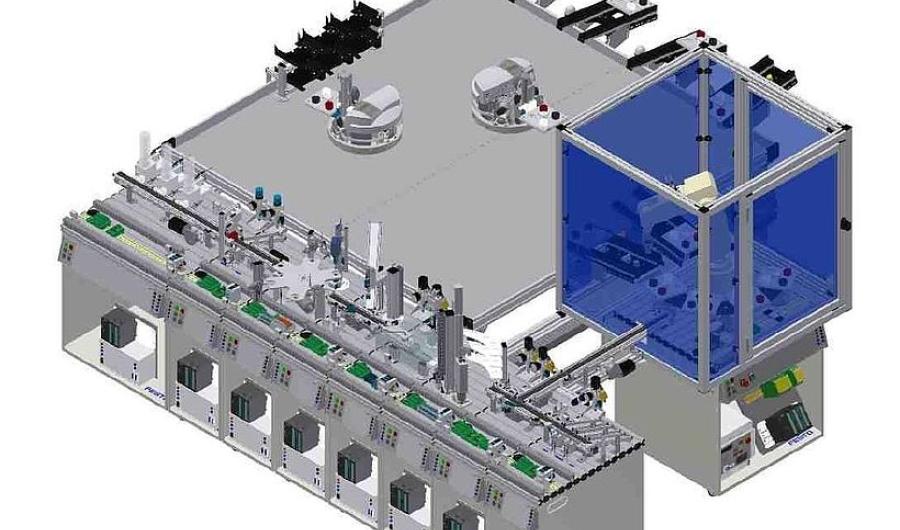

Technology: AI, digital twin technology, AR/VR technology, assistance system, robotics

Precise hand movements are very important to many application areas such as gaming, virtual and augmented reality, robotics, automation and medical technology. Digitizing manual assembly, induction processes for new employees can be established faster and more effectively in a business. Using intelligent data gloves, tasks of long-term employees can be recorded, saved and made available as learning material.

The data glove has 7 IMUs per hand, each sensor providing 7 different measured values. A total of 48 parameters per glove are measured. 30 frames per second, 86,400 measured values per minute.

Where can you access this demonstrator?

Hub Cottbus. At the BTU Cottbus-Senftenberg, BTU Cottbus-Senftenberg; Siemens-Halske-Ring 14; 03046 Cottbus