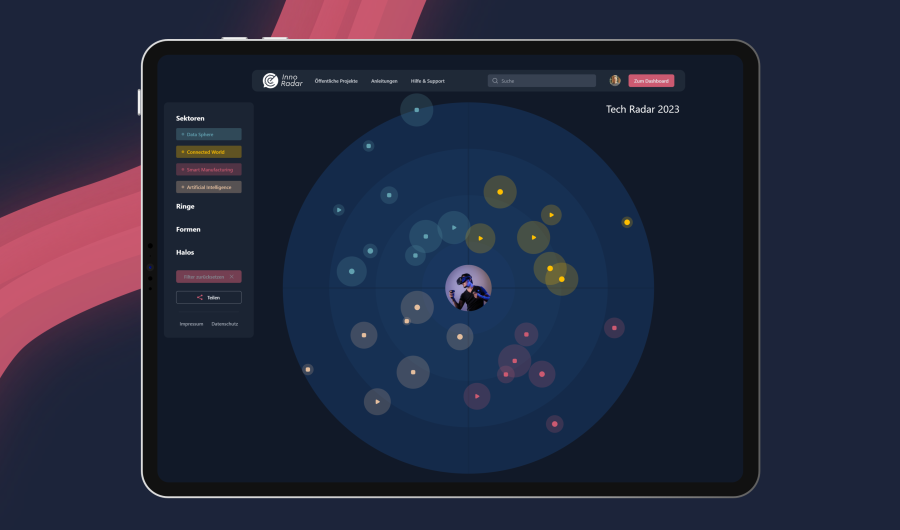

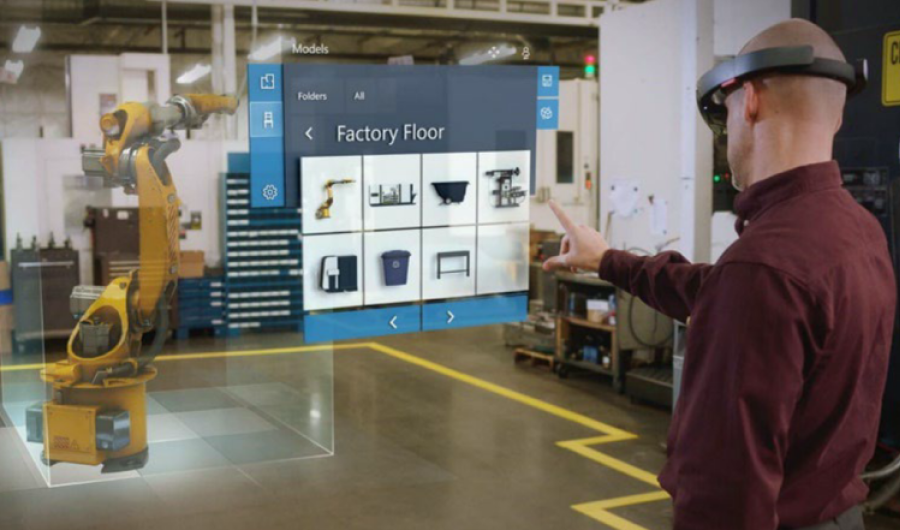

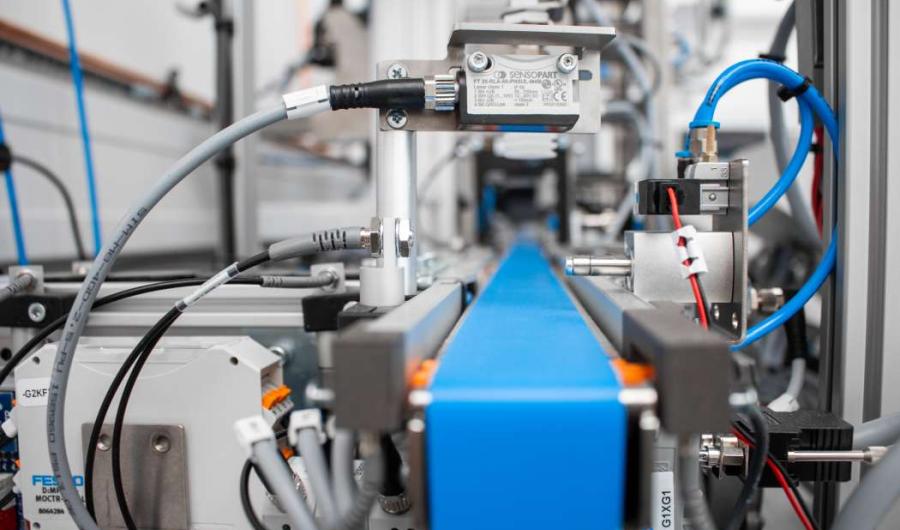

Virtual factory environment for visualization and problem solving

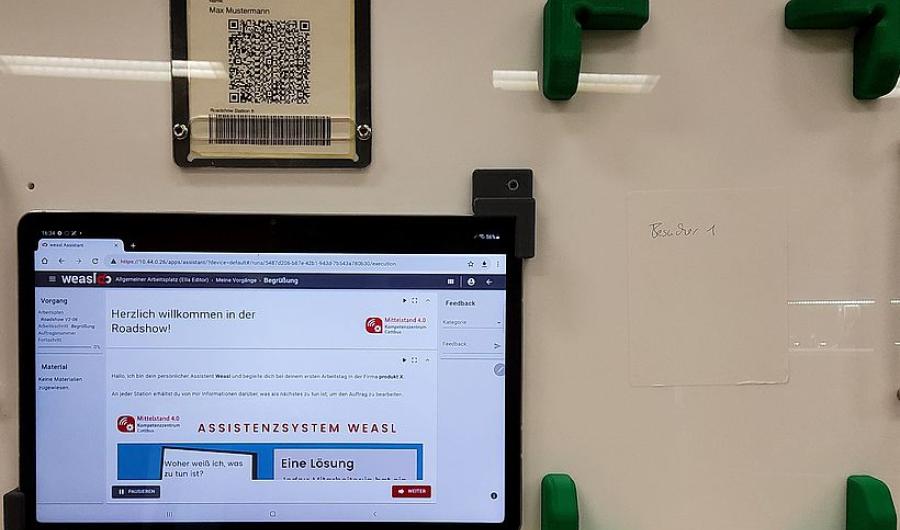

For SMEs VR is becoming increasingly interesting, because it is now affordable and accessible and helps to save explicit and implicit knowledge loss by high employee turnover.

VR can identify production losses and challenges early on at a much more cost-effective rate. Product and production environments can be easily inspected without huge, expensive set-up.

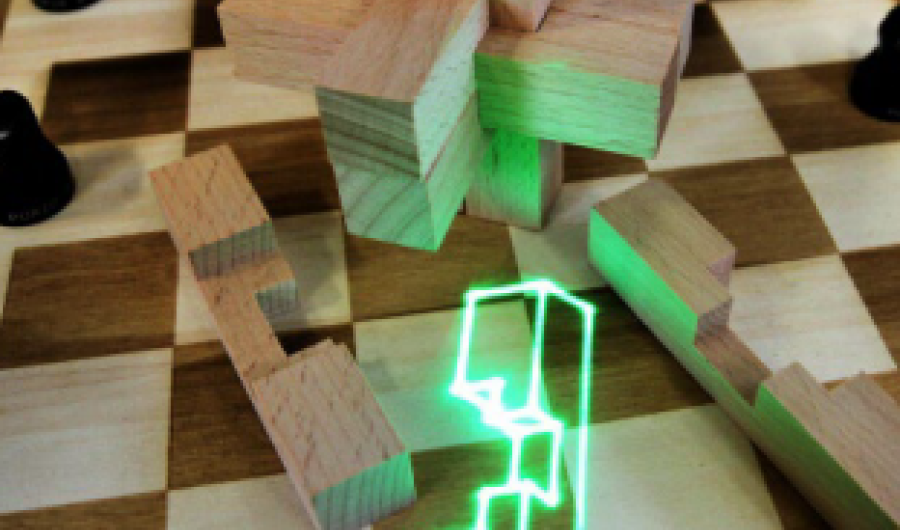

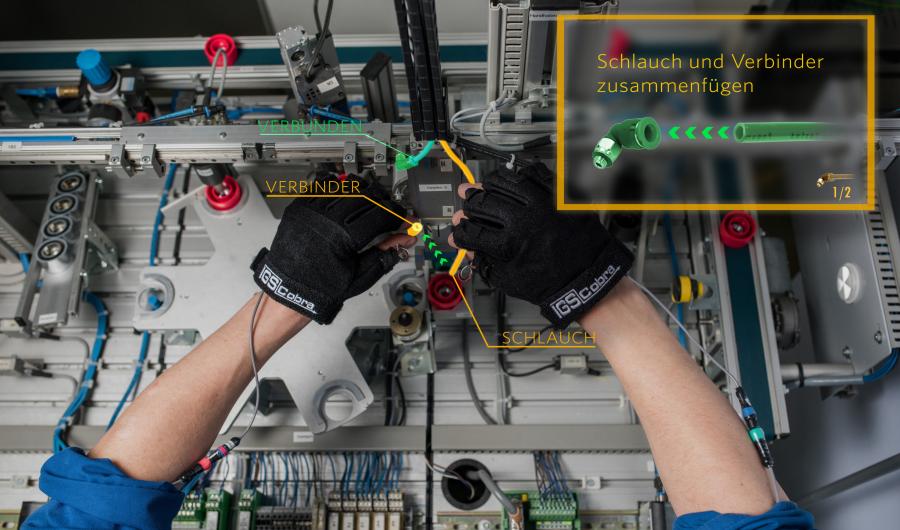

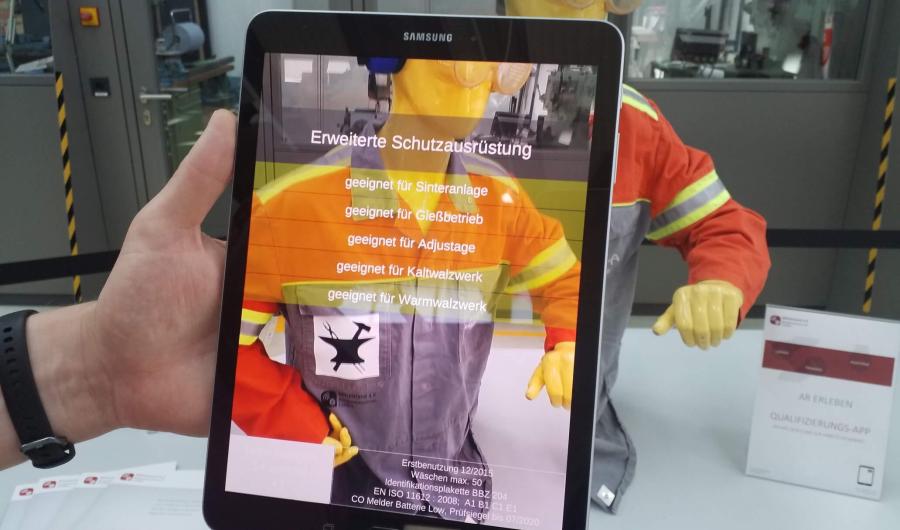

Interactive testing without danger makes VR interesting for interacitve learning aswell.

VR offers a wide range of applications for companies, who are looking to partly digitize their processes and learnings. When digitalizing construction and process data sufficiently, this can even boost the marketability in the age of Industry 4.0.

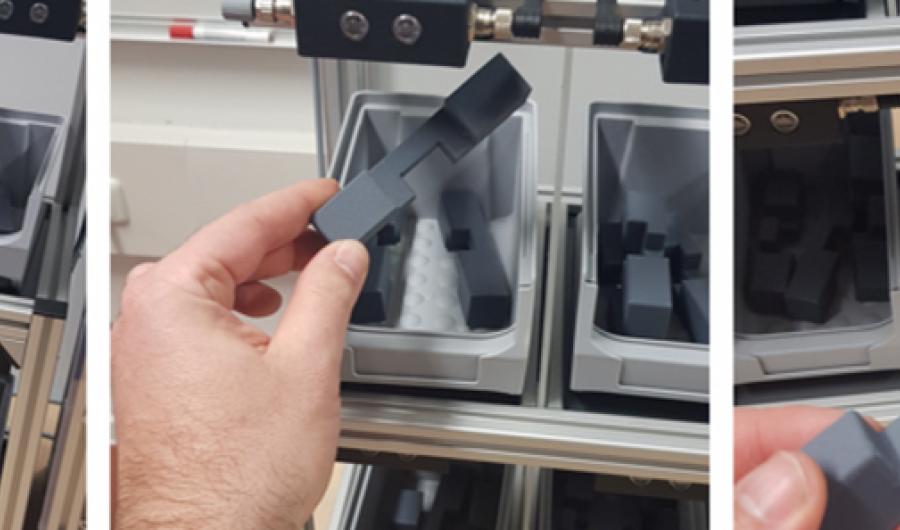

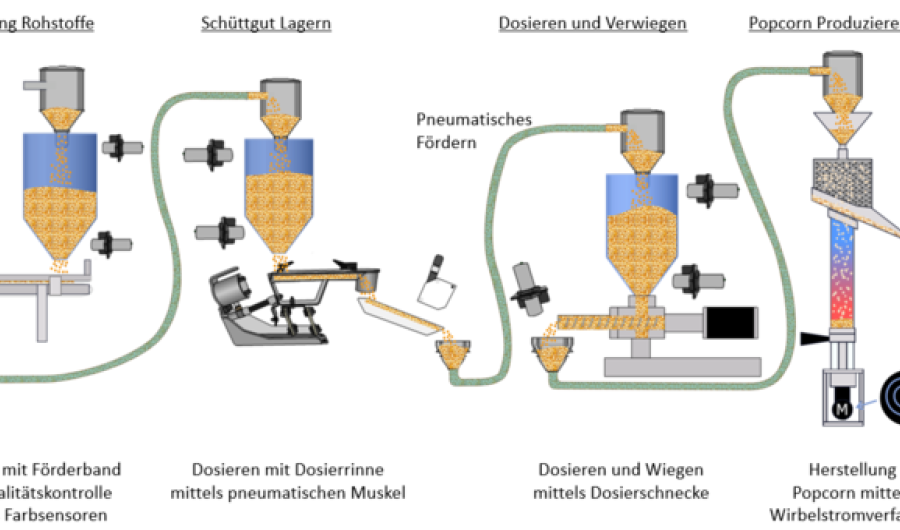

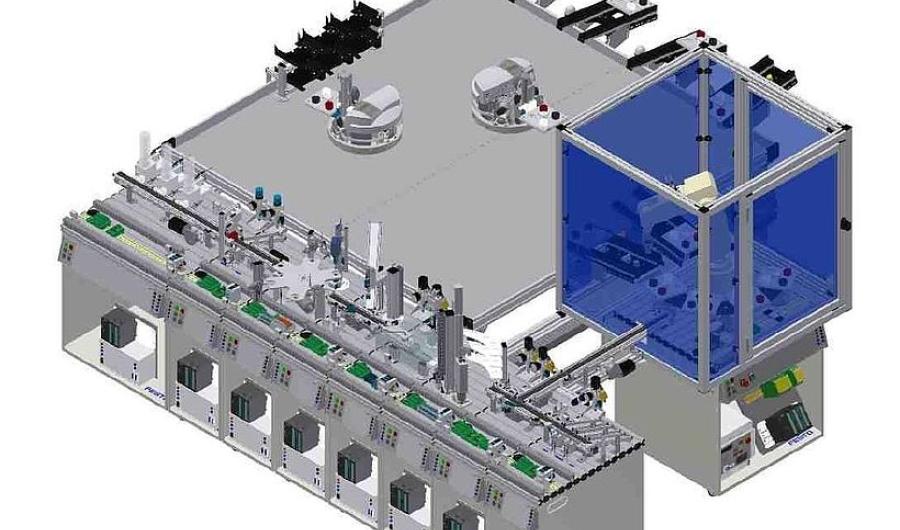

Virtual factory environment, that was created at the university, can be used to visualize interactively work on problems and possible solutions in the value chain. By means of gamification, assembly processes based on CAD and assembly instructions can be experienced without the real product environment.

Technology: Digital twin technology, AR/VR

Where can you access this demonstrator?

Hub Cottbus. At the BTU Cottbus-Senftenberg, BTU Cottbus-Senftenberg; Siemens-Halske-Ring 14; 03046 Cottbus