The Roadshow – Mobile PickSecure

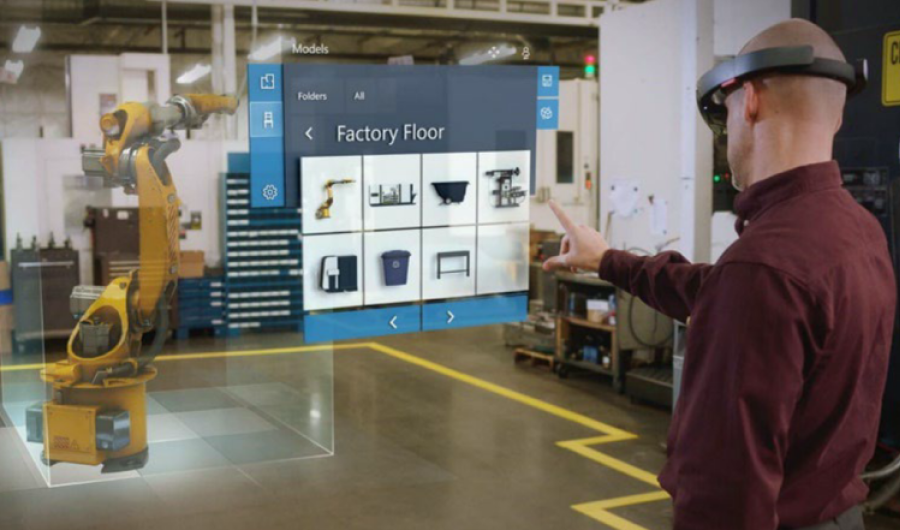

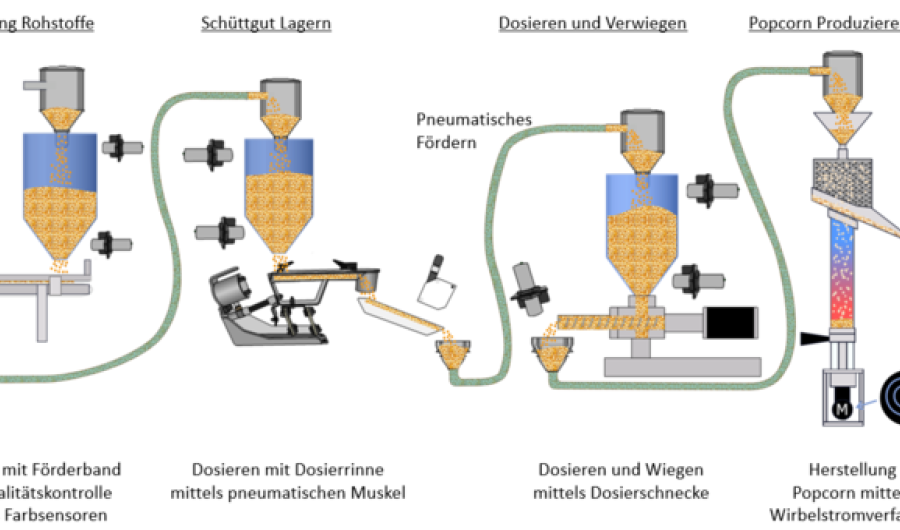

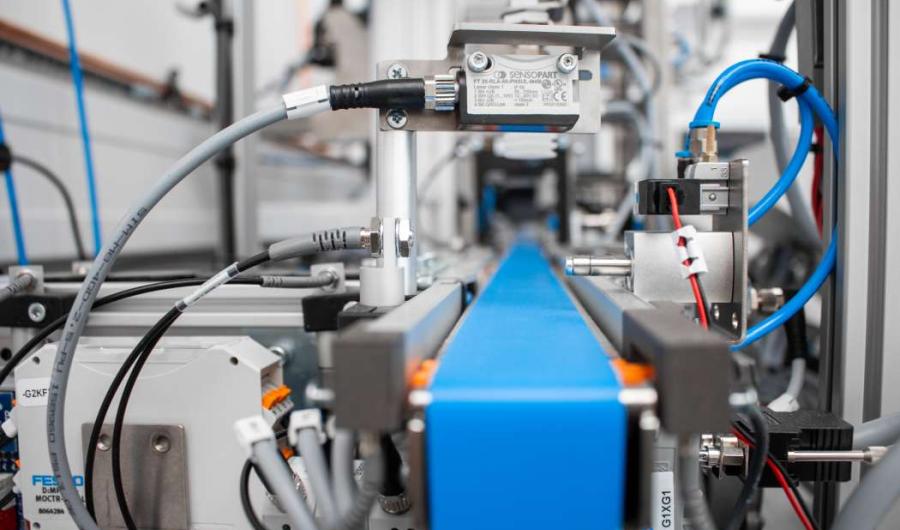

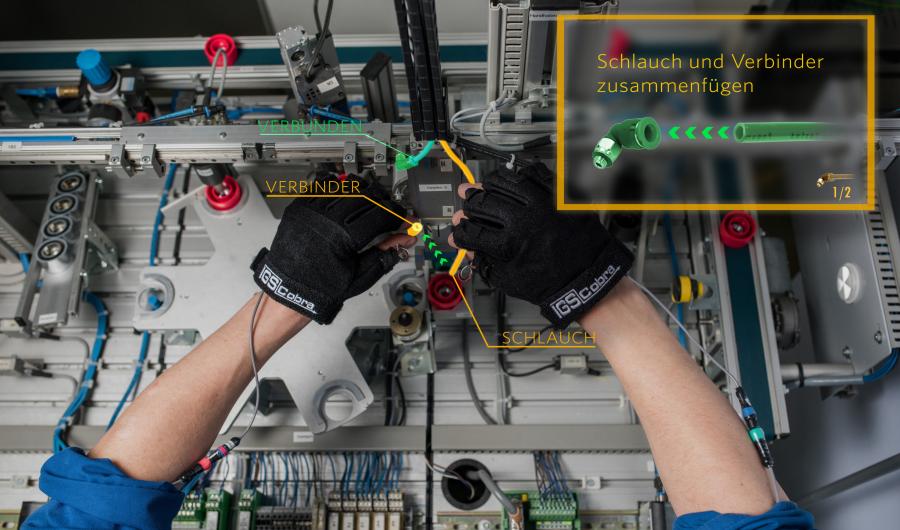

Modern production systems are characterized by automated, intelligent networking of machines and processes through the use of information and communication technologies. Even in automation, especially in assembly, there is still work that has to be done manually.

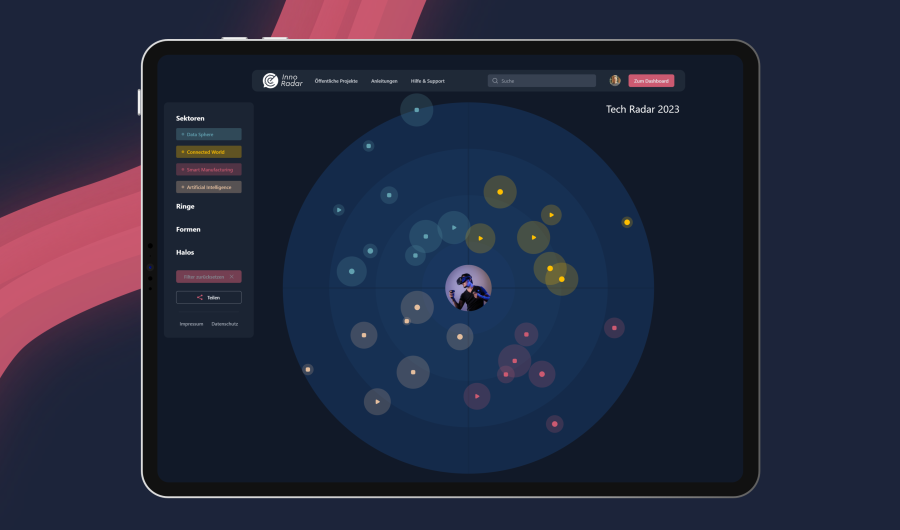

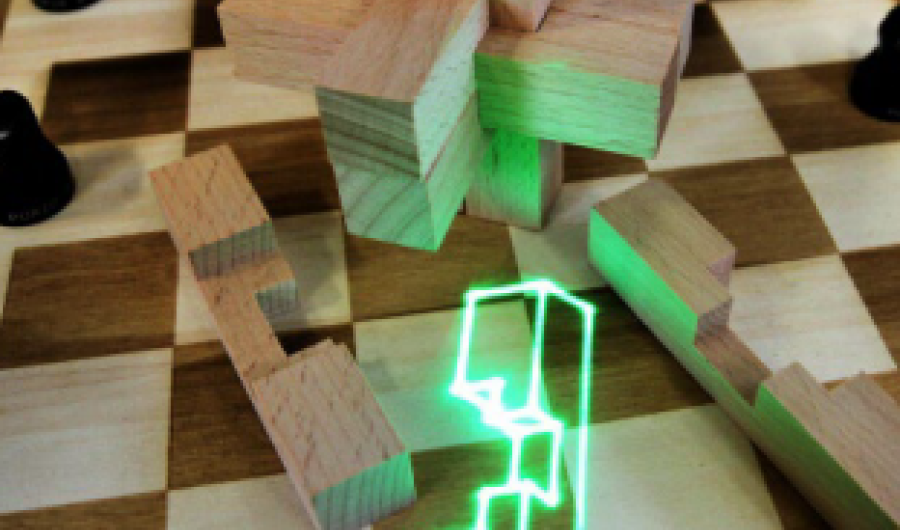

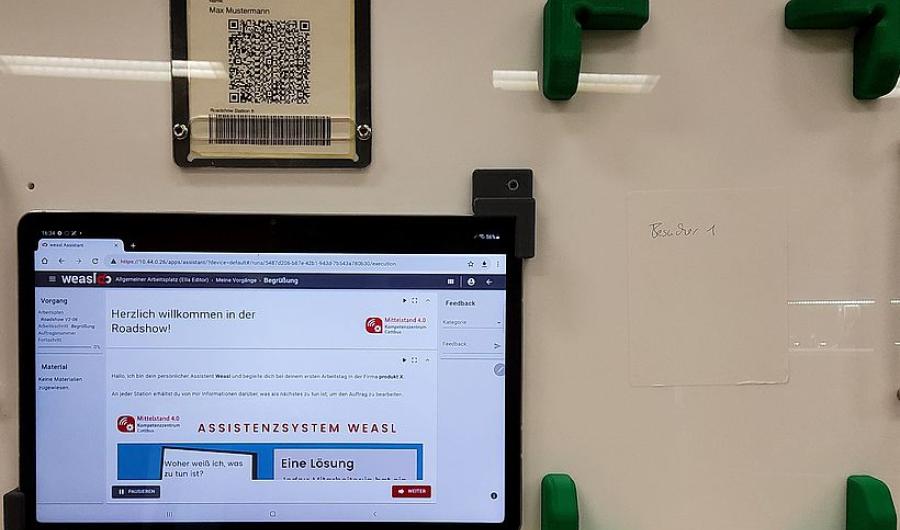

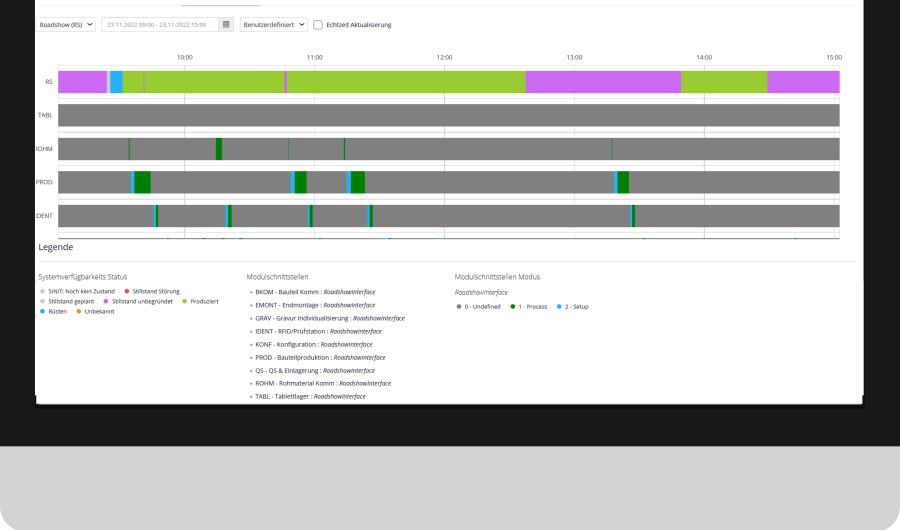

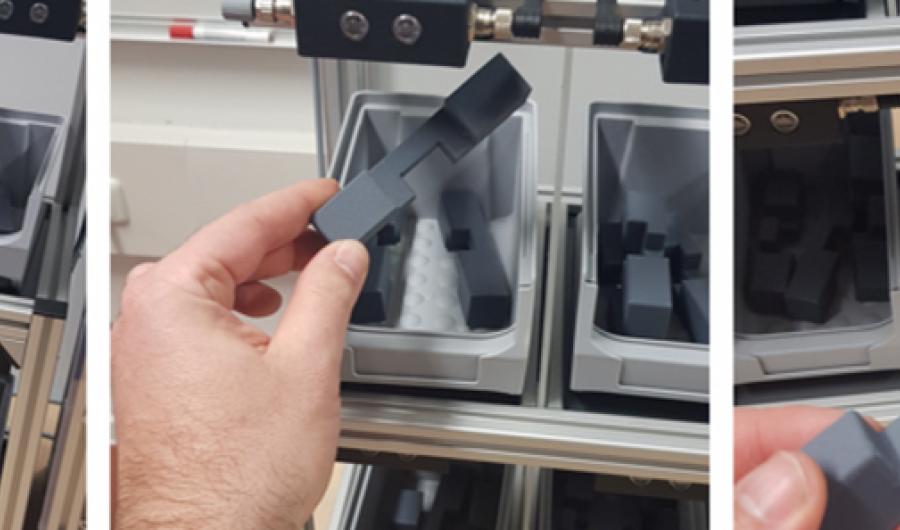

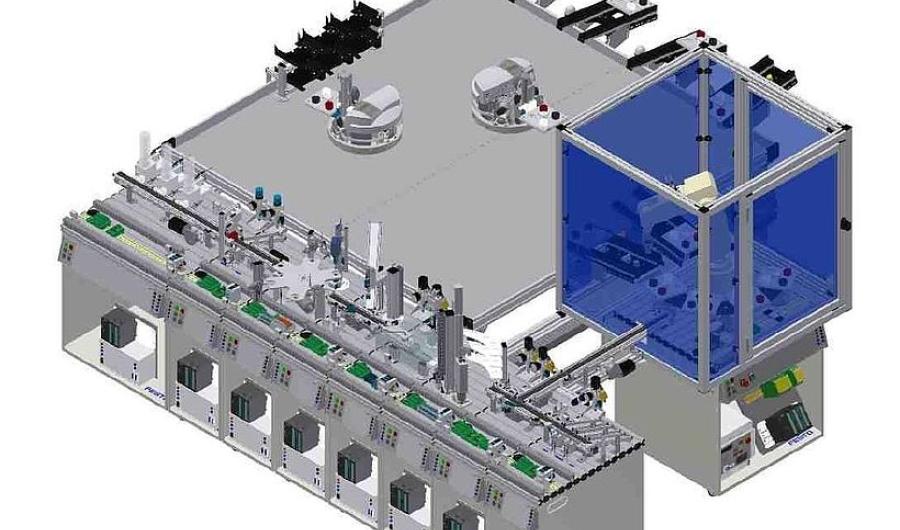

In the Roadshow Mobile PickSecure a system was developed to optimize this work, to reduce errors through built-in quality control and to shorten the general assembly time, e.g. by means of better and simplified material provision. Sensors and signals are used to determine the removal of the correct materials in the correct assembly sequence. In addition, the material stock is monitored. Therefore an upcoming bottleneck situation can be avoided by loading of the assembly workstation in a timely manner.

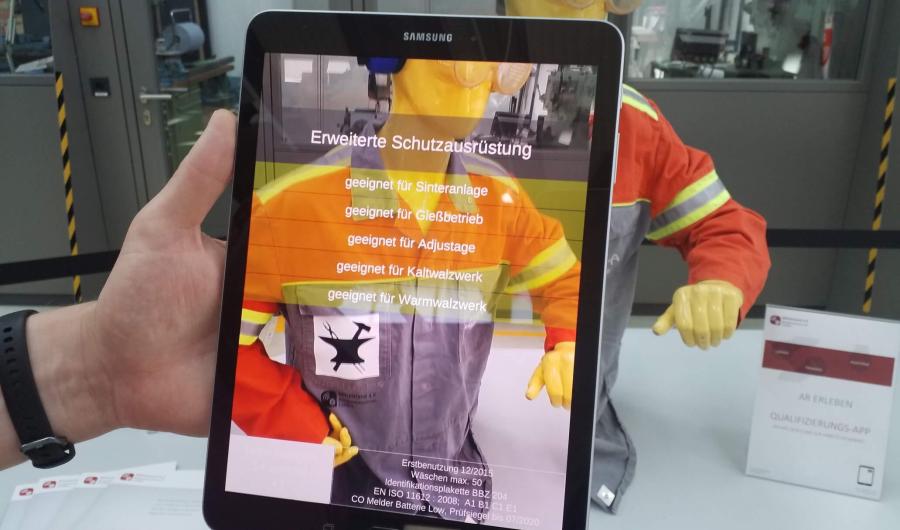

Area of application: The assistance system presented in this demonstrator is suitable in modified forms for any assembly operation. Both small businesses and large internationally operating companies can benefit from this methods. The demonstration scenario presented is particularly suitable for assemblies with a high number of variants.

Where can you access this demonstrator?

This demonstrator can be tested directly at your company, as it can be transported with little effort from the Hub in Wildau and easily integrated into existing processes at your location. This makes it easier for companies to assess their digitalisation potential and also allows their staff to train on the use of new technologies.