The devil's knot - human-machine interaction

The challenge you are facing

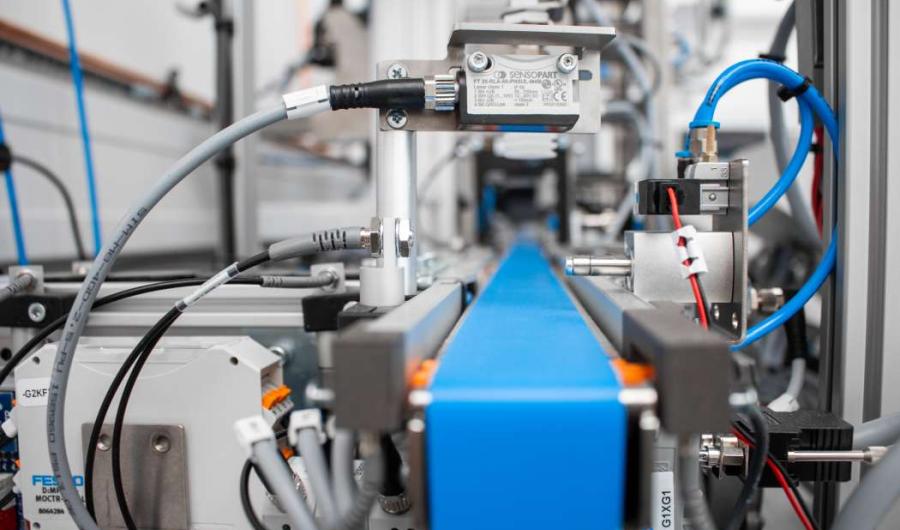

Assembly in companies and production facilities is essential. Especially where there is a frequent change in production, the assembly instructions should be as simple and understandable as possible, not least for the new employees, for example, to make training easier.

Solution

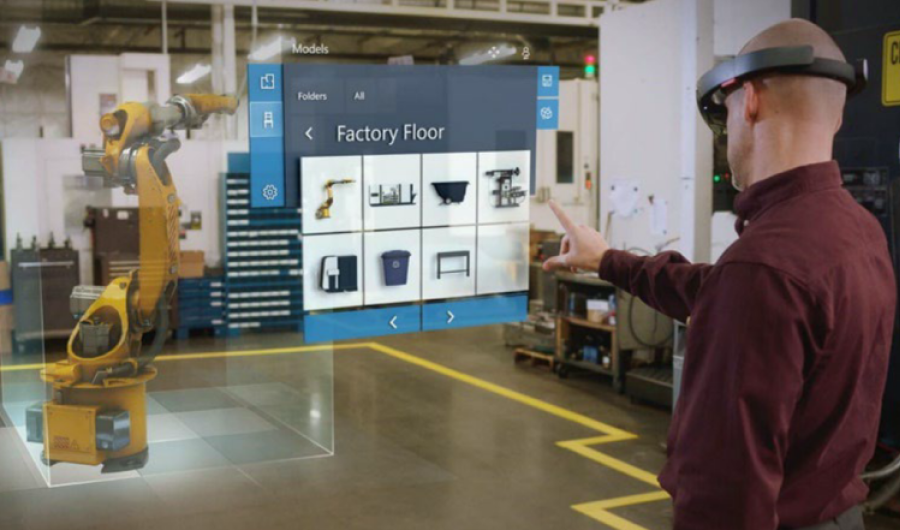

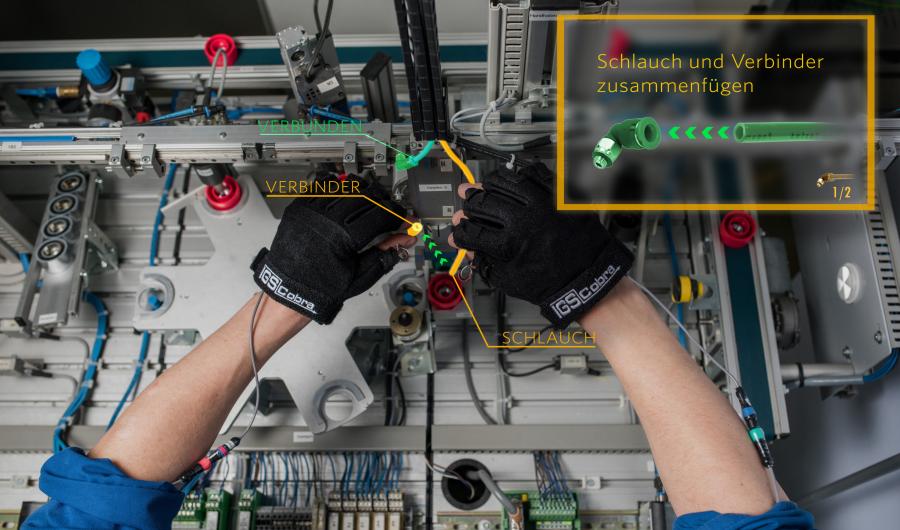

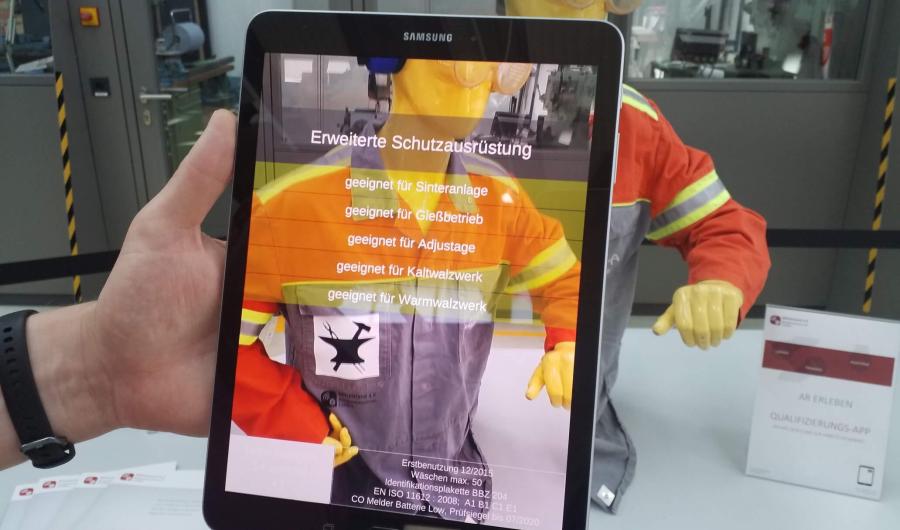

The special feature of this technology is the combination of visual assistance and the possibility of going through the various inspection and assembly steps by means of voice control. This leaves the user's hands free and he can concentrate fully on the production steps. Furthermore, appropriate communication with the user is also possible. Queries or requests for repetition of the instructions are therefore very easy to manage.

In addition, the error rate is minimized, since only certain commands can be named. This also speeds up the production process. It also facilitates the training of new employees or new tasks.

Technologies: Artificial Intelligence, human-machine interaction, voice recognition, LASER projection

How does it work?

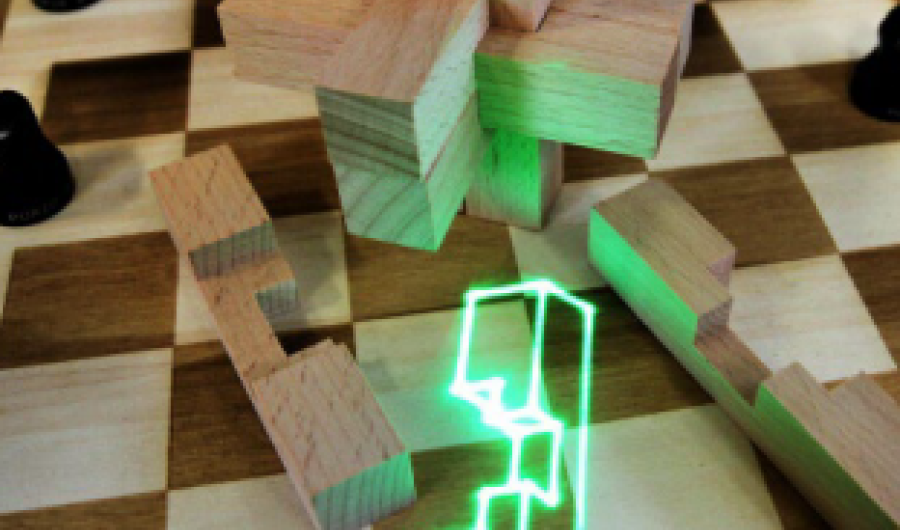

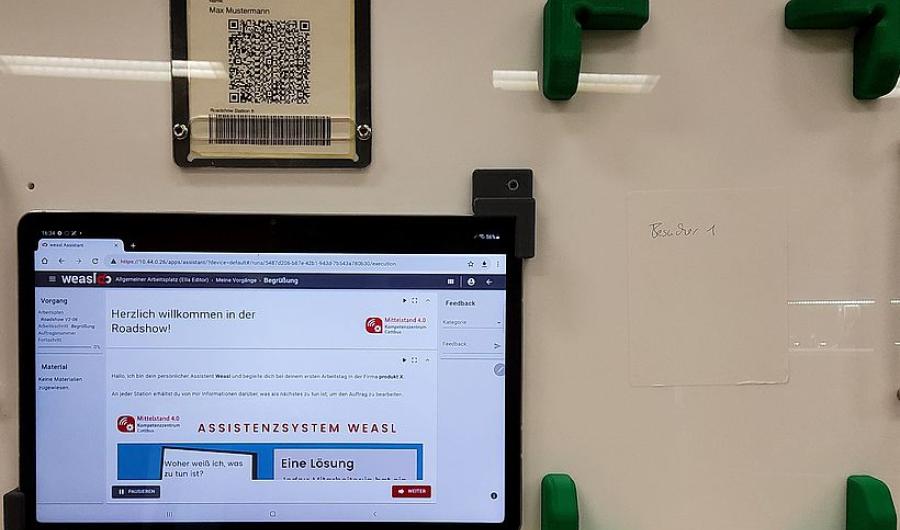

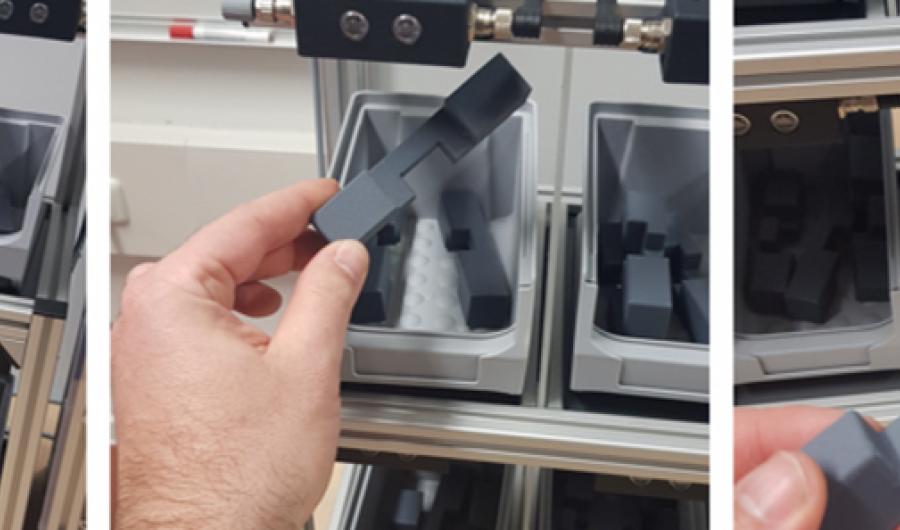

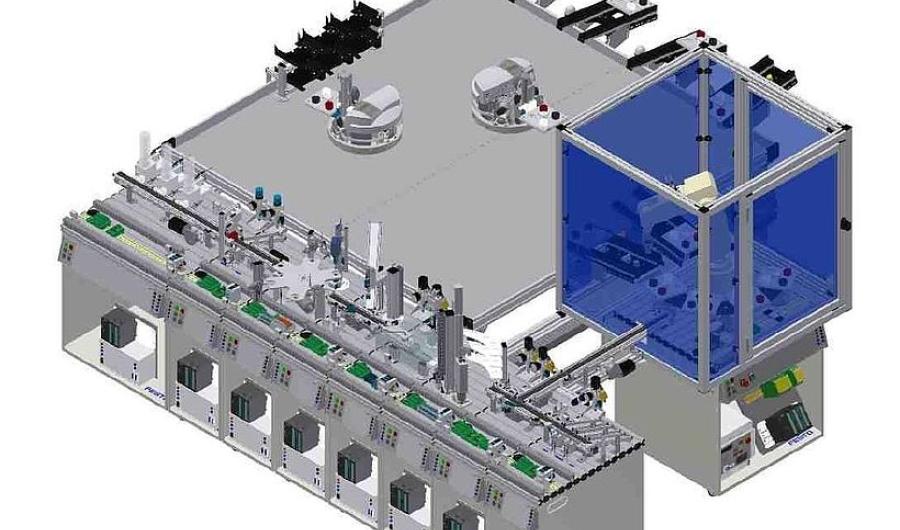

The demonstrator shown in the roadshow shows the assembly of the devil's knot with the help of KIM. KIM is an acronym for the german sentence "AI in Medium-sized businesses" and offers the possibility to easily perform the assembly of the devil's knot by means of voice control and a LASER projection. By the voice control the hands are free and one can devote oneself completely to the assembly, in addition, to the examination of the individual parts.

Furthermore, through the voice control, which can only perform certain commands, the error rate is kept low and productivity has thus also been optimized.

Where can you access this demonstrator?

The demonstrator can be tested directly at the company and be easily integrated into the existing infrastructure. This way, companies see directly the benefits of digitization in a low-threshold way and train their employees on modern technologies.