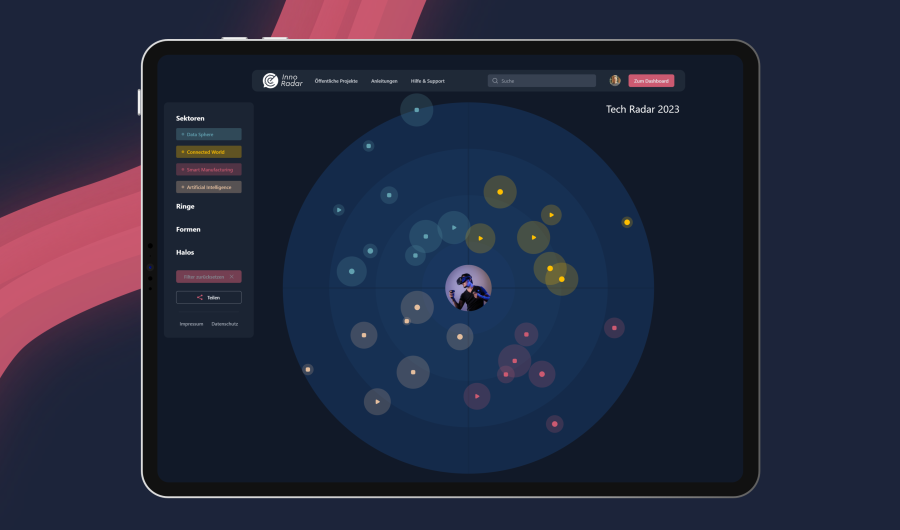

Augmented Reality Learning Glasses: HoloLens (LTA4Glasses)

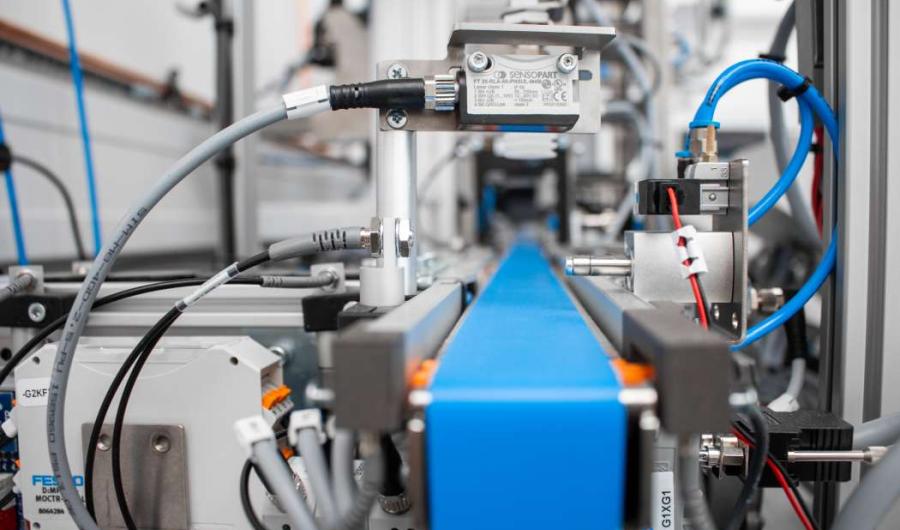

In new and complex assembly processes some tasks require repeated accuracy and consistency in terms of quality, regardless the process duration or employee assigned to this.

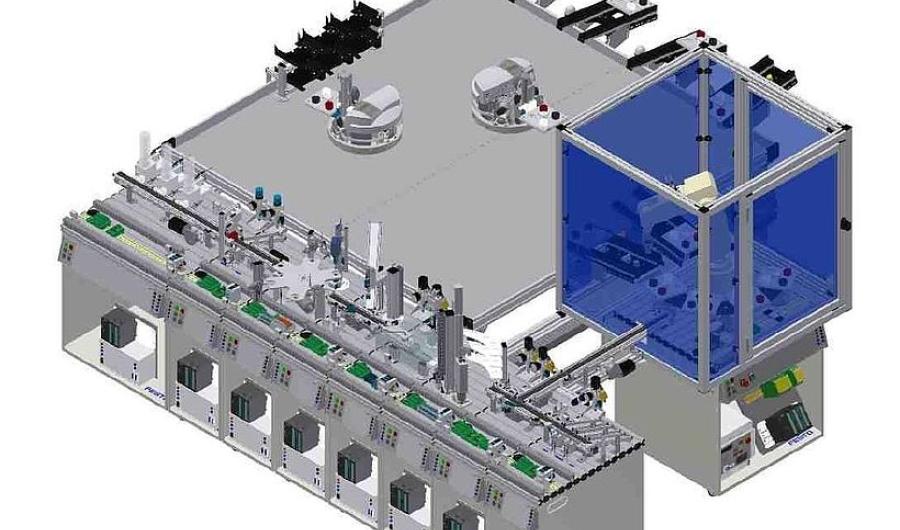

This demonstrator, the HOLOLens, offers individual, location and time-independent learning of assembly and repair processes, with easy repetition of the training unit. This "digital process training" leads to time savings in qualifications:

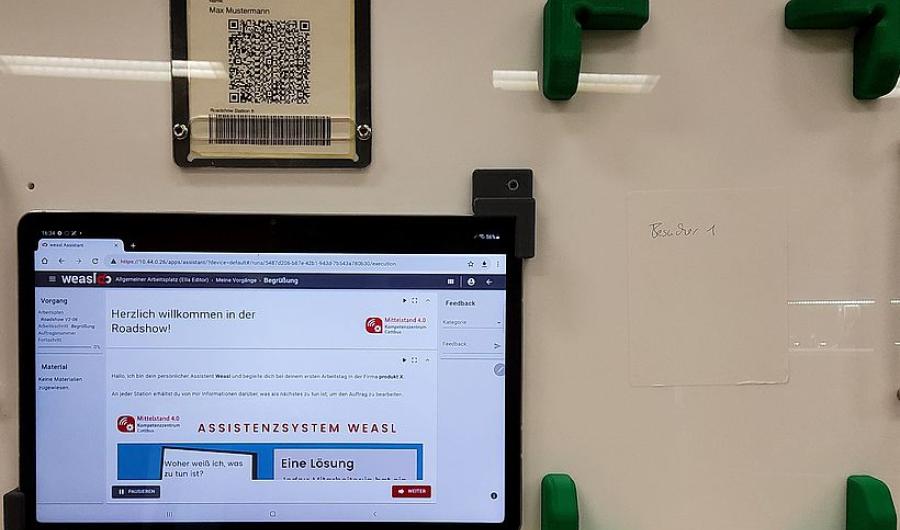

Learning and training takes place reliably and repeatedly at any time with these learning glasses.

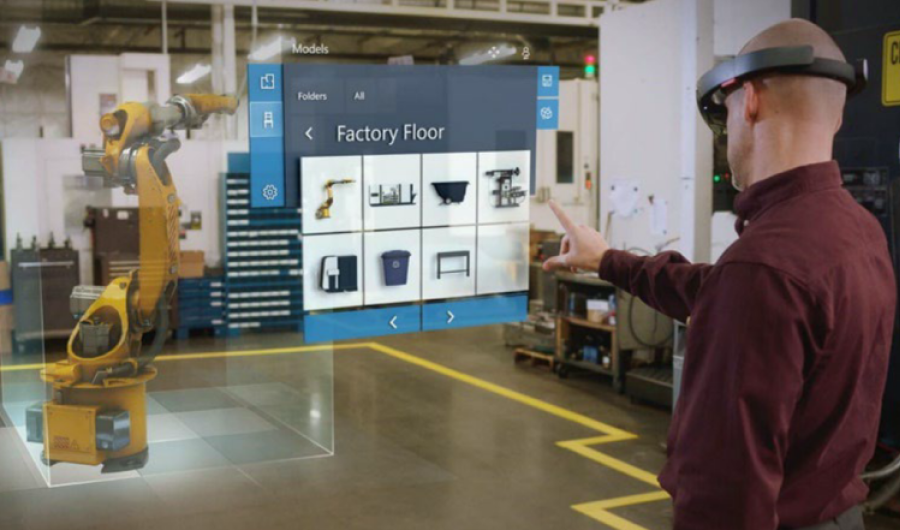

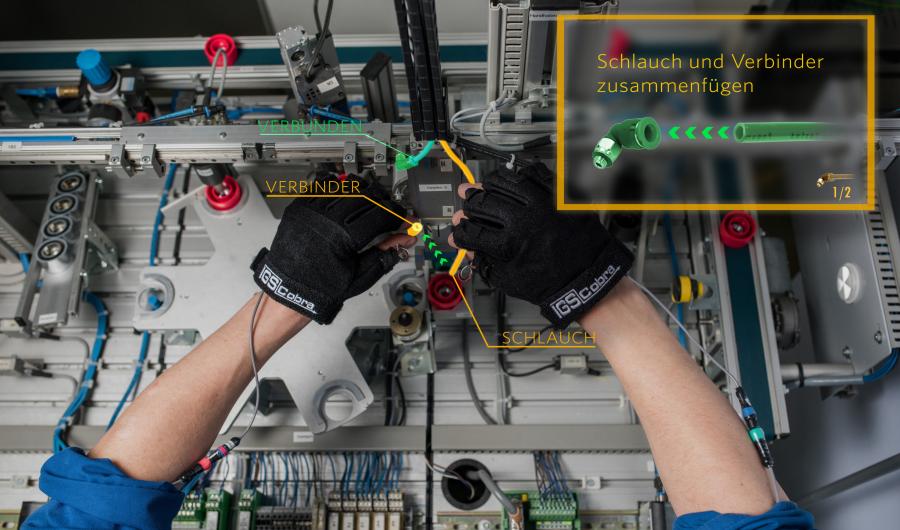

An additional hands-free assistance system offers lessons through AR, texts, images or other elements superimposed on reality. Assigned tasks can be trained, performed and maintained on a high quality level.

Onboarding processes of new hires, change in the workforce or change of a workprocess become more easily.

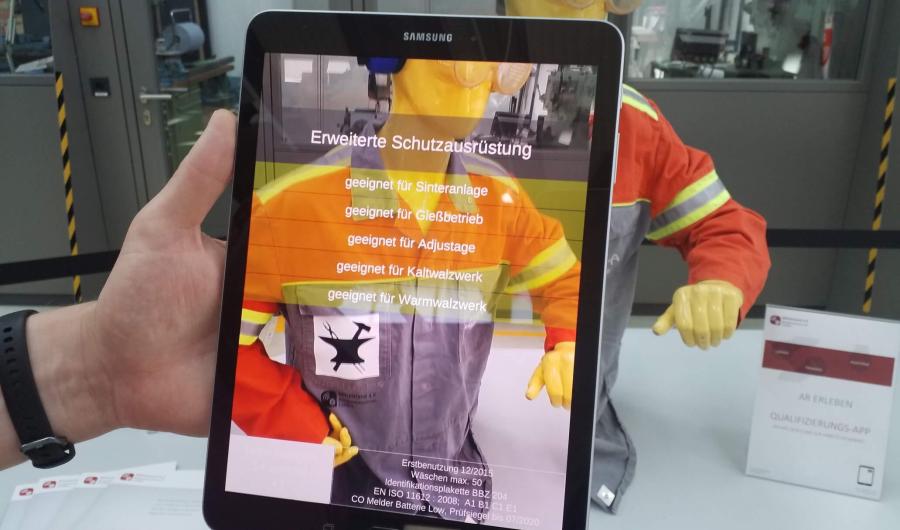

This acquires extra devices such as a Smartphones or AR glasses that display the real environment, which also enable to display computer graphics at the same time.

Technology: AI, digtial twin technology, augmented/virtual reality, assistance system

Learning processes through visual demonstration of assembly tasks

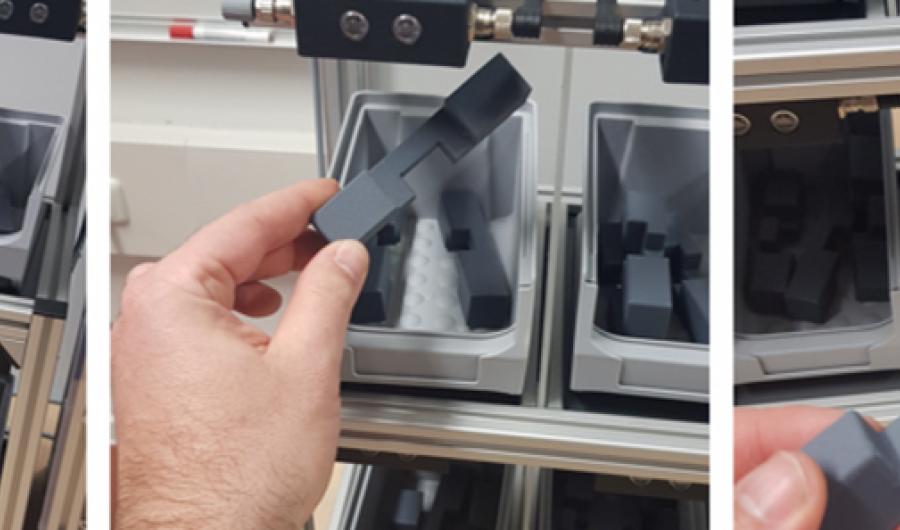

In the training, assembly processes are repeated virtually with the trainees hands

During the assistance program, processes are repeated with relevant real components.

The real assembly movement is transmitted in real time to the digital screen in the AR glasses. The correct assembly is displayed on the screen of the AR glasses.

Where can you access this demonstrator?

Hub Cottbus. At the BTU Cottbus-Senftenberg, BTU Cottbus-Senftenberg; Siemens-Halske-Ring 14; 03046 Cottbus